Water assisted injection molding introduction

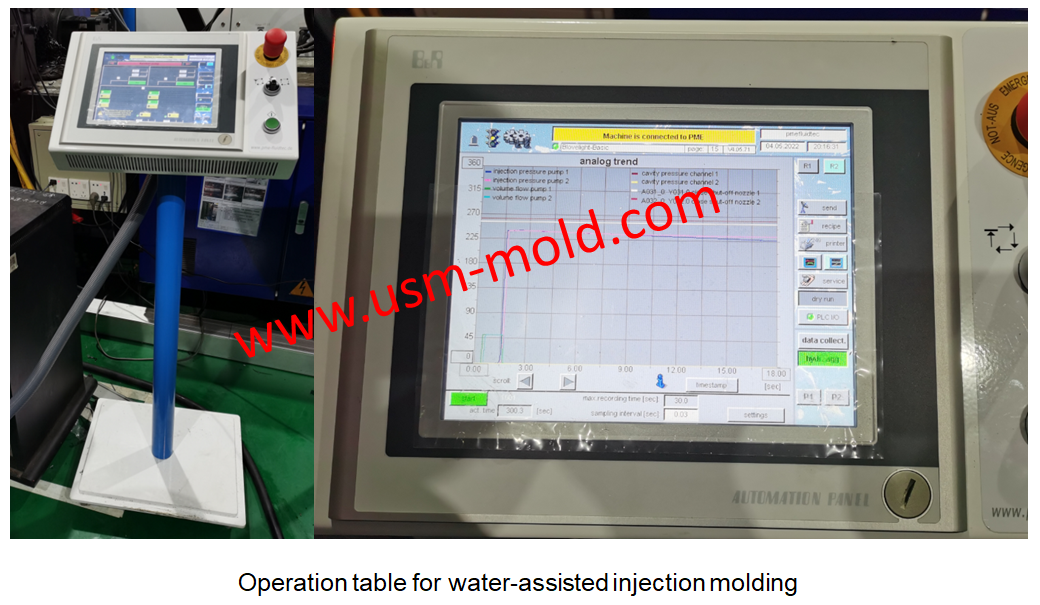

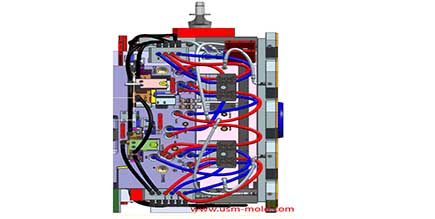

Like the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic back and force the workpiece to form a hollow state. Research and applications have shown that water-assisted parts can make thinner and more even wall thickness parts which means material savings. In addition, comparing to gas-assisted injection molding, water-assisted injection molding can produce larger and smoother inner walls. Comparing with gas-assisted injection molding with nitrogen, the main advantage of water-assisted injection is the rapid cooling efficiency of water, the thermal conductivity of water is 40 times higher than nitrogen, and the heat capacity of water is 4 times larger than gas. For thick-wall parts, the cooling time of water-assisted and gas-assisted can be reduced by 30-70%. The main difference between gas and water is that gas can be compressed but water cannot. The higher viscosity and incompressibility of water make the front end of the water form a solid interface, which acts as a squeezing hammer to hollow out the workpiece, the front side of water also serves to cool the melt filled into the cavity and core.

.png)

The main difference between water and gas is that gas is compressible but the water is not. because of the viscosity and incompressibility of water relative to gas that water can play a role in hollow molding. When the water is injected in a way that the water will not evaporate during the injection, the front side of the water acts like a moving plunger on the melt center of the part. from the front side of the water to the transition section of the melt, the plastic with a thin solidified layer membrane, it is like a high-viscosity core to further push the polymer melt, thereby hollowing out the part, while the water pressure pushes it forward, the water also cools the melt, the gravity or compressed air is used to drain the water from the workpiece and flow into a storage tank fat the end, where the water can be recycled. Water injection moulding can greatly shorten the molding cycle of products, and can be used to produce lightweight and strong hollow products with good appearance effects.

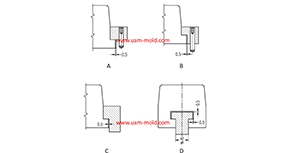

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

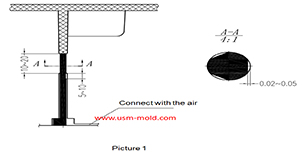

Insert pin of vengting design for molded parts

Mar 20, 2022Insert pin of venting: It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end...view

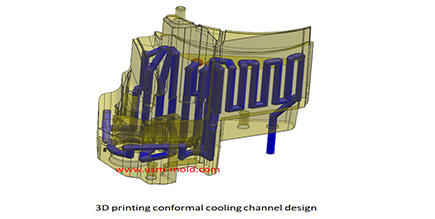

Plastic injection mold cooling system design notice

Feb 14, 2022Design notice of designing the cooling system: 1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer; 2....view

Pin-point gate of plastic injection mold runner system design

Jan 24, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

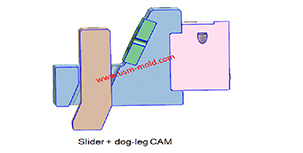

Classification of side parting and core pulling mechanism

Jul 17, 2022According to the structural characteristics of plastic moulding, the side core-pulling mechanisms are divided into the following six categories: 1. The side core-pulling mechanism of "slider + guide...view

Design principle of plastic injection mold cooling system

Feb 13, 2022Design principle of cooling system In order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in...view

English

English русский

русский