The principle of mold temperature balance in plastic mold cooling system design

The principle of mold temperature balance:

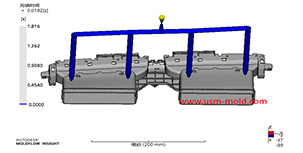

1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be make the mold temperature as balanced as possible, and there should be no local overheating or overcooling.

2. The high temperature areas in the mold including: near the sprue bushing, near the gate, and near the thick wall of the plastic part, these areas should be cooled.

3. Heating is sometimes required at thin-walled areas.

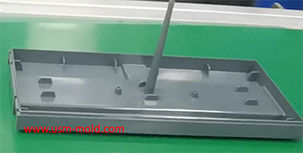

4. During the cooling process of the mold, due to the phenomenon of thermal expansion and contraction, the plastic part will slightly detach from the fixed mold cavity when the solid shrinks, while the tightening force on the core is getting bigger and biggger, and the plastic part is detaching, the more heat before demolding is transferred to the core, so the core must be focused on cooling.

5. To control the temperature difference of the cooling water at the inlet and outlet of the cooling channel, the temperature difference should be less than or equal to 2°C during precision injection molding, and in general, the temperature difference should be less than or equal to 5°C. the total length of the cooling gate (series length) should not be too long, preferably less than 1.5m, and the length of the dead zone should be as short as possible.

6. The cooling channel must be designed for the stripper in the three-plate mold, t, so that the mold temperature can be stabilized during the production process and the molding cycle can be shortened.

.png)

Plastic injection mold runner system design points

Jan 9, 2022When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...view

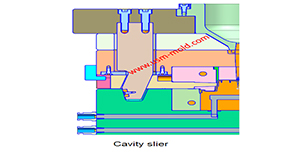

What is the side parting and core pulling mechanisms with their function?

May 31, 2022When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...view

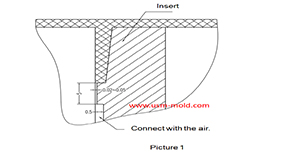

Venting insert design of molded parts

Mar 13, 2022In the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw...view

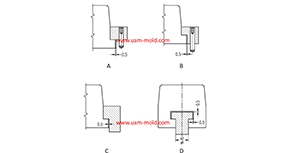

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

Direct gate of plastic injection mold runner system design

Jan 19, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Unique Solutions Mold Profile

Dec 27, 2021USM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square...view

English

English русский

русский