The common fixing method of angle pin

The angle pin is a common part of the drive slider, and the fixing and installation methods as following:

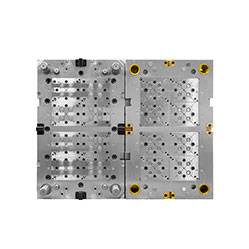

1. Pass through the mold plate directly and press the angle pin with the top plate to fix it, as shown in picture 1.

This installation method is suitable for the case where the formwork is thin and the tope plate is not separated from the A plate, the matching surface is long and the stability is good, the matching tolerance of the angle pin and the fixed plate is H7/m6, disassembly and maintenance are very complex, the mold plate must be disaasembled when changethe angle pin.

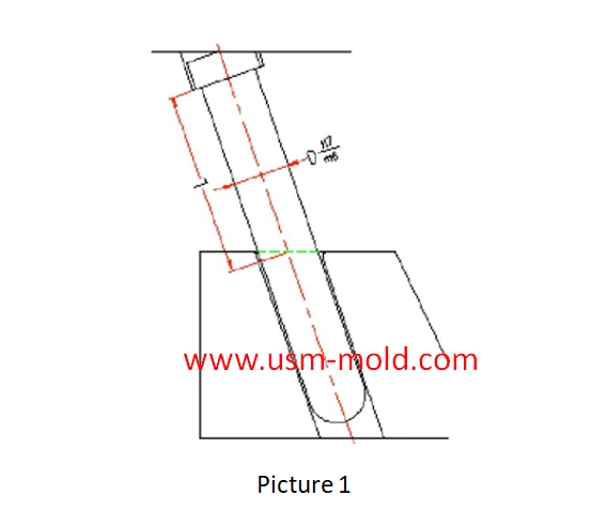

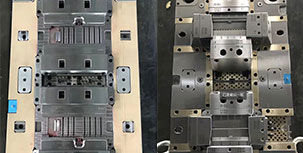

2. Pass through the template directly and press the angle pin with the pressing block to play a fixed role, as shown in picture 2.

This installation method is suitable for the case where the formwork is thin and the top plate is separated from the A plate, the matching surface is long and the stability is good, the matching tolerance of the angle pin and the fixed plate is H7/m6, installation and maintenance are very complex, and the plate must be disassembled to replace the angle pin.

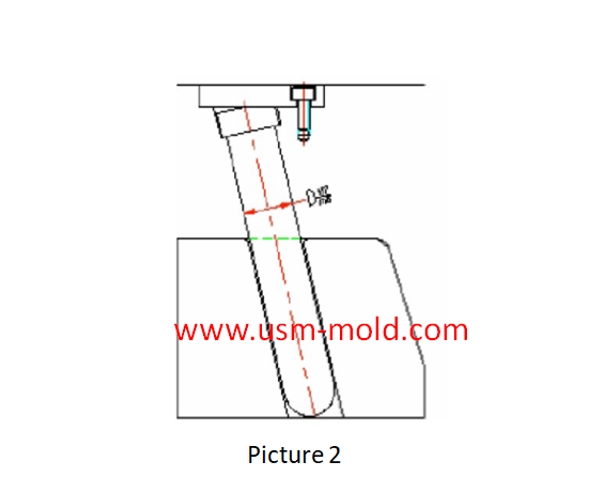

3. The angle pin does not pass through the plate, and the angle pint is still fixed on the plate, but the hole for fixing theangle pin is a blind hole, and a screw is used at the back to tighten the angle pin, this kind of angle pin has no steps, as shown in picture 3.

This installation method is suitable for use in the case of thick plate, and both two-plate and three-plate mold can be used, and the mating surface L needs to be bigger than 1.5D, this installation method has poor stability, and is difficult to process and maintain in the future.

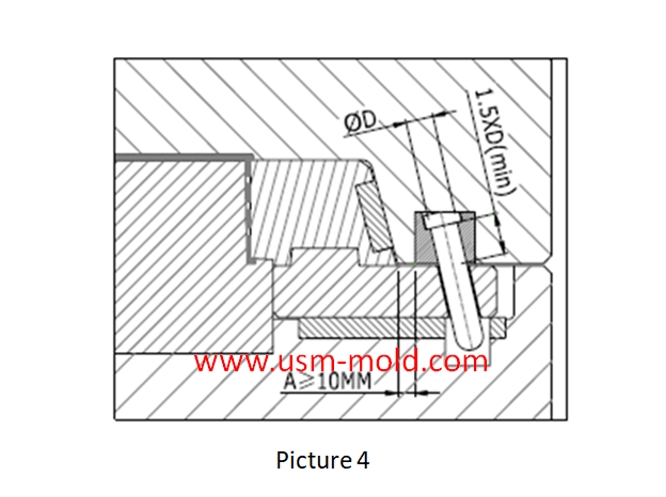

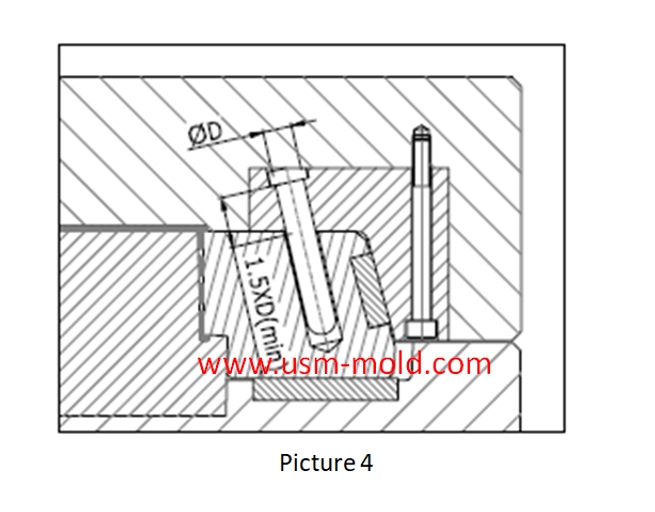

4. The angle pin is not installed in the plate, but is installed in a movable block which is fixed to the plate from the front with screws, the movable block can be disassembled from the front of the plltae, see the picture 4.

This installation method is suitable for use in the case of thick plate, both two-plate with three-plate mold can be used, and the mating surface L needs to be bigger than 1.5D, this installation method has good stability, and is very convenient for processing and maintenance, it is a more common used installation method.

5. The angle pin is not installed in the plate, but is installed in the locking block, this locking block is fixed to the plate from the front with screws, the locking block can be disassembled from the front of the plate, as shown in picture 5.

This installation method is suitable for use in the case of thick plate, both two-plate and three-plate mold can be used, and the mating surface L needs to be bigger than 1.5D, this installation method has good stability, and is very convenient for processing and maintenance, it is also a more common used installation method.

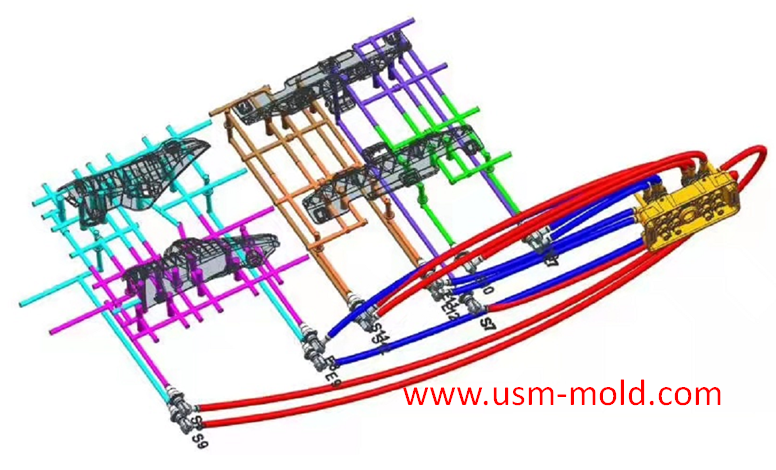

Temperature system of injection mold

Feb 8, 2022Hi everyone,the mold cooling time is the longest during injection, so the design of mold temperature system controlling is very important, we will talk about mold cooling, heating system in following...view

The common fixing method of angle pin

May 10, 2024The angle pin is a common part of the drive slider, and the fixing and installation methods as following: 1. Pass through the mold plate directly and press the angle pin with the top plate to fix it,...view

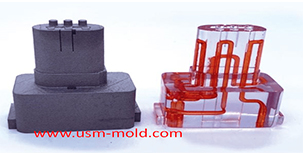

Conformal cooing channel of plastic injection mold

Feb 23, 2022The conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product...view

Vacuum venting mold design for plastic molded parts

Mar 23, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

What is Plastic Injection Mold?

Dec 27, 2021The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

English

English русский

русский