The basic points of designing gas-assisted injection molding

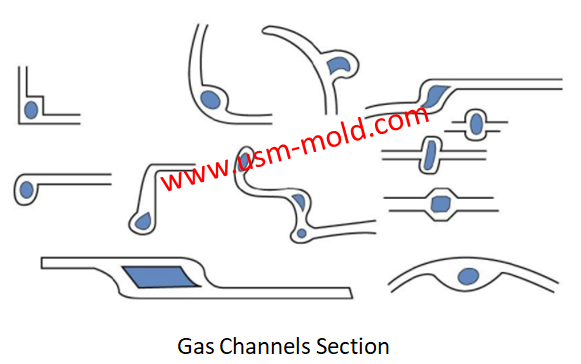

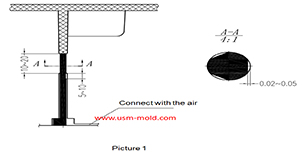

1. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel;

2. The gas channel should be arranged in balanced and cannot return back;

3. The layout of the gas channel should be consistent with the main material flow direction, and a larger fillet radius should be used at the corners;

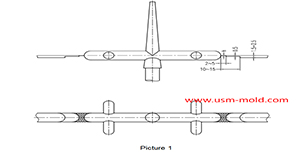

4. The gas nozzle should be placed at the farthest place from the last filling place of the plastic, and placed at the wall thickness area, keeping a distance of more than 20mm from the gate;

5. When the gas is injected, it must be a clear flow direction and it can go to the end of the gas channel;

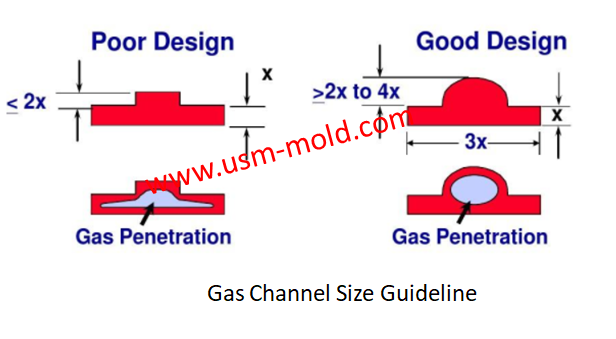

6. The size of the gas channel is very important, generally 2~4 times than the wall thickness, if the gas channel is too big will cause welding line and air trapping, and if gas channel is too small will cause the gas flow out of control;

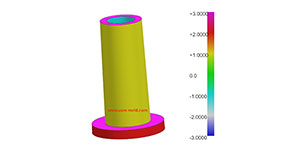

7. The cooling should be as even as possible, and the temperature difference between the inner and outer part should be as small as possible, then make a block in half diameter gate area to control the gas flow speed in different directions.

Parting surface venting of runner system

Mar 10, 2022There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...view

Insert pin of vengting design for molded parts

Mar 20, 2022Insert pin of venting: It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end...view

Banana gate of plastic injection mold runner system design

Feb 7, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view_20250317091113A018.jpg)

The basic points of designing gas-assisted injection molding

Apr 17, 20221. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel; 2. The gas channel should be arranged in...view

What is Called Draft Angle?

Dec 29, 2021The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in picture 1....view

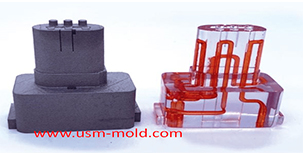

Conformal cooing channel of plastic injection mold

Feb 23, 2022The conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product...view

English

English русский

русский