The air trapping position in cavity and exhaust method

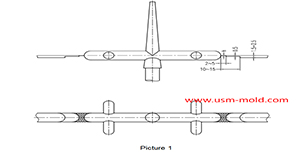

The air trapping in cavity is usually in the following places:

1. Thin-wall structure cavity, the end of melt flow;

2. The junction of two or more melts;

3. The last area where the melt in the cavity reaches;

4. The bottom of the blind hole of the mold cavity is mostly the end of a solid column in the part;

5. Reinforcing ribs of molded parts and the bottom of screw pillars;

6. Dead corners of complex mold cavities.

.png)

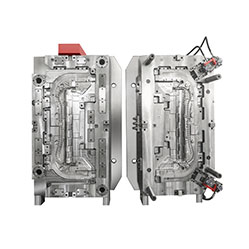

Exhaust method in injection mold include as following:

1. Parting surface (including venting slot);

2. The fitting surface of insert;

3. The fitting surface of the push rod or pipe with inner mold insert;

4. Exhaust from side core pulling mechanism;

5. Add a vent needle or insert to vent the air in the trapped area;

6. Breathable steel exhaust;

7. Air valve exhaust;

8. The mold is evacuated and exhausted.

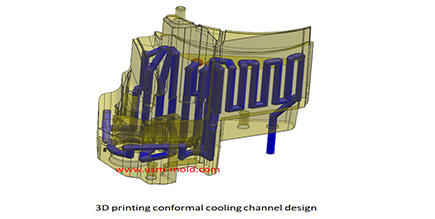

Design principle of plastic injection mold cooling system

Feb 13, 2022Design principle of cooling system In order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in...view

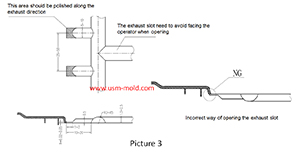

Design standard of exhaust slot

Mar 3, 2022The exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...view

Direct gate of plastic injection mold runner system design

Jan 19, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Five Major Steps of the Injection Mold Production Process

Dec 9, 2021Injection mold manufacturing can be roughly divided into the following steps: Process analysis of plastic products. Before the mold design, the designer should fully analyze and study whether the...view

What is Ejection Molding?

Dec 28, 2021The process to get injection molded products is called injection molding, or called injection. Injection molding is an important method in polymer molding processing, it is characterized by a short...view

Parting surface venting of runner system

Mar 10, 2022There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...view

English

English русский

русский

_20250310164515A048.webp)