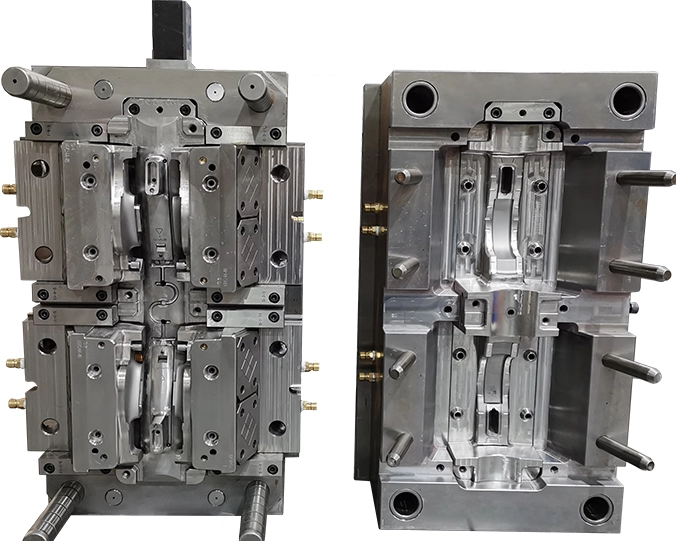

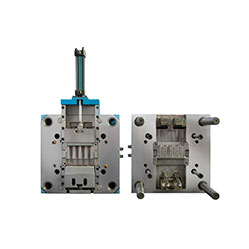

Slider of side core pulling mechanisum assembling

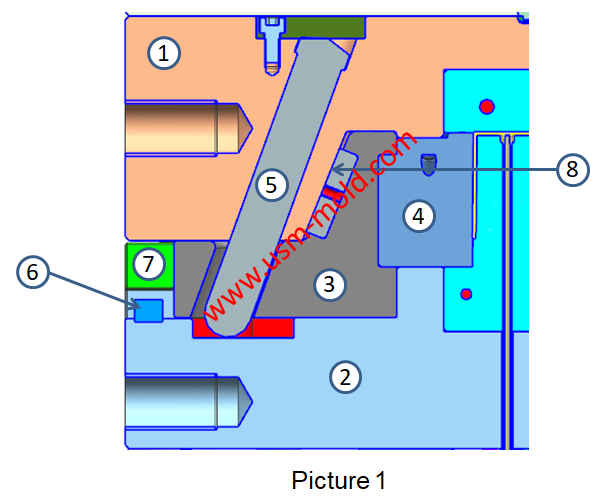

The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.

1. Lateral forming parts: the lateral forming part is the lateral concavo-convex (including the side hole-shaped parts, including the lateral cores and forming blocks, etc.) of the molded plastic parts, such as the slider insert 4 in picture 1;

2. Moveable parts: moveable parts refer to the parts that install and drive the lateral forming blocks or cores and move inside the guide pin, such as the slider which shows in picture 1;

3. Transmission parts: the transmission parts refer to the parts that drive the moving parts for side parting when the mold is opened or to reset when the mold is drawn and closed, such as the inclined angular pin 5 in picture 1, the types of transmission parts are: dog-leg CAM drive, hydraulic cylinder drive, air cylinder drive, etc.;

4. Locking parts: in order to prevent the moving parts from being displaced by lateral pressure during injection, the parts set are called locking parts, such as the wedge tightening surface 8 in picture 1;

5. Limiting parts: in order to make the moving parts stay in the required position after the side parting or core pulling, to ensure that the transmission parts can be reset smoothly when the mold is closed, the moving parts must be set in the lateral direction, the limit parts at the end of parting or lateral core pulling, such as limit block 6 in picture 1;

6. Guide parts: the guide parts refer to the slider that restricts the slider to move in the correct direction when moving, as shown in the guide rails 7 in picture 2.

Plastic part ribs desigining

Jan 4, 2022The ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of the...view

Limitations of gas-assisted injection molding technology

Apr 25, 2022Gas-assisted injection molding technology has obvious advantages in thick wall thickness and pipe parts, but this technology still has many limitations, which are mainly reflected in the following...view

USM Blogo Opening

Oct 27, 2021Hello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need. USM is a professional plastic injection mold and molding...view

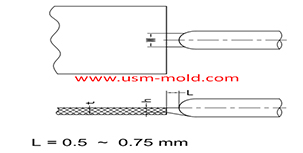

Plastic injection mold runner system design

Jan 16, 2022The gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate...view_20250317090912A017.jpg)

Several common process of water-assisted injection molding introduction

May 24, 2022According to the design of the injection molding machine and the casting system, the corresponding melt-returning process of water-assisted injection molding can be roughly divided into two types: the...view

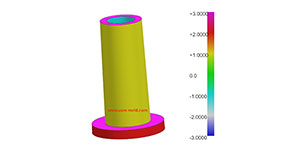

What is Called Draft Angle?

Dec 29, 2021The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in picture 1....view

English

English русский

русский

_20250311083139A052.webp)