Slider designing tips 2

9. The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;

10. When using the center guide slider, we should follow the company standard "slide center guide slider design" strictly;

11. When the mold is closed, if there is a risk of interference between the slider and other parts, the reset mechanism must be done first;

12. The core-pulling distance of the slider must be bigger than the actual core-pulling distance of the product by 3-5mm;

13. The large slider should be avoided to be set in the direction of the top side of the mold as far as possible; if it is unavoidable, it should be driven by an hydralic cylinder, and a stroke switch should be installed to cooperate with it;

14. When the cylinder core-pulling device is not used for the slider on the day side, the strength of the slider limit device must be checked to ensure that the weight of the slider does not exceed 2/3 of the strength of the limit device to prevent accidents;

15. When the slider is set on the ground side, the spring can be cancelled, but at the same time, a reliable stop should be designed to prevent the slider from falling off due to its own weight;

16. The same material cannot be used if there is frictional movement between the parts or the requirements of the insertion.

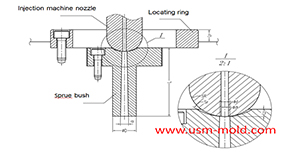

The main design points of the design of the plastic mold pouring system

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

Limitations of gas-assisted injection molding technology

Apr 25, 2022Gas-assisted injection molding technology has obvious advantages in thick wall thickness and pipe parts, but this technology still has many limitations, which are mainly reflected in the following...view

What is Ejection Molding?

Dec 28, 2021The process to get injection molded products is called injection molding, or called injection. Injection molding is an important method in polymer molding processing, it is characterized by a short...view

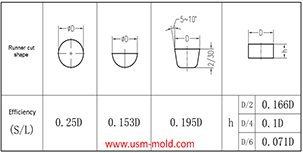

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

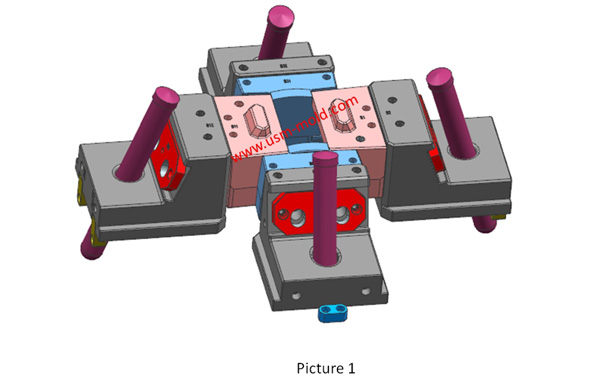

The design requirements of slider wear plate

Jan 2, 20241. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...view

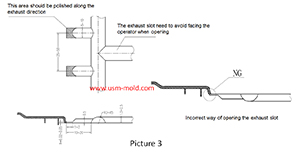

Design standard of exhaust slot

Mar 3, 2022The exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...view

English

English русский

русский