Reasons for making the exhaust system of the injection mold

The gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in high temperatures. During injection molding, these gases should be exhaust in time, otherwise there will be some issues as following:

1. Defects such as flow mark, water mark, and weld marks will be formed on part surface;

2. Defects such as bubbles and loose tissues inside the plastic parts, which will lead to insufficient filling inside plastic part;

3. It is difficult to fill the plastic melt or flash locally;

4. The gas generates high temperature under high temperature and high pressure, causing local carbonization and burnt marks on the product;

5. Reducing the filling speed of the plastic melt, not only the molding cycle is prolonged, but the melt temperature decreases quickly after injection speed dropped, the residual stress will increase, if the injection pressure is increased, and the possibility of warping deformation of the plastic part after demolding will increase, if the material temperature is increased in order to reduce the injection pressure, it will cause the plastic to crack.

Properly making the exhaust slot can reduce the injection pressure greatly, reduce the injection and the holding time, and reduce the clamping pressure, thereby improving the production efficiency, reducing the production cost, and the energy consumption of the machine. For transparent plastic parts or plastic parts with strict surface requirements, we should be careful with the mold exhaust system design.

Plastic injection mold runner system design points

Jan 9, 2022When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...view

Plastic cooling factors by injection parameter

Feb 10, 20221. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately...view

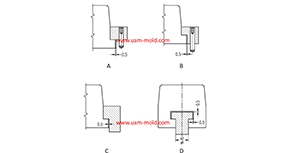

The T slot of slider and guider designing tips

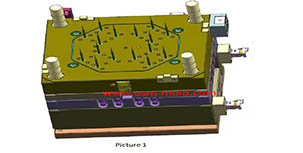

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view_20250317091228A019.jpg)

Main application of gas-assisted molding technology

Apr 7, 2022Gas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

Limitations of gas-assisted injection molding technology

Apr 25, 2022Gas-assisted injection molding technology has obvious advantages in thick wall thickness and pipe parts, but this technology still has many limitations, which are mainly reflected in the following...view

English

English русский

русский