Direct gate of plastic injection mold runner system design

In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among them, the side gate is divided into tab gate, ear protection gate, fan gate, thin gate and so on, the sub gate is divided into sub gate, banana gate, downturning gate and so on.

According to the production automation, it is divided into manual removal and automatic removal, the side gate and direct gate are need to be manually removed after production,but the sub gate and pin-point gate and valve gate of hot runner are automatic removed, we wil dicuss the direct gate today:

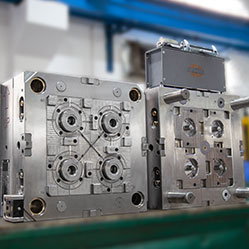

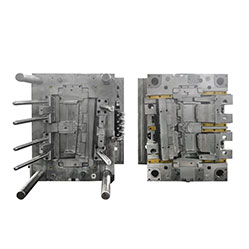

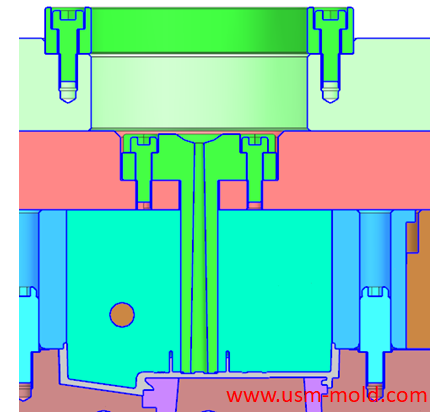

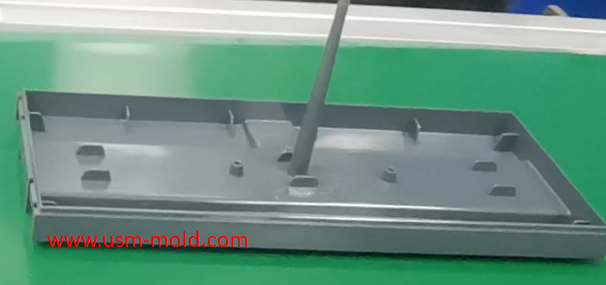

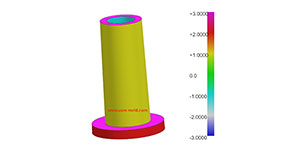

Direct gate (Sprue gate): direct gate is also called main runner type, the plastic enters the cavity directly through the main runner, as shown in picture 1a and picturee 1b.

Picture 1a

Picture 1b

Advantage:

1. The product size is accurate and the molding quality is good, due to the gate size is big which is less affected by other external factors, so the part size of is better controlled during injection molding, and the injection molding process range is also big;

2. Saving runner processing, the direct gate is usually the gate sleeve that directly enters the product (as shown in picture 1a), and the direct gateh is a standard part, which is already processed after buying it, and there is no need to process the main runner and sub runner on the mold core etc.;

3. Less pressure loss, the direct gate size is generally big, and it is directly injected into the product from the nozzle of the injection molding machine, without the conversion between the main runner and the sub runner, so the process is shorter and the injection pressure loss will be relatively small;

4. Products with large or depth can be formed, because the gate size is bigger than that of the general gate, the flow length ratio of the product will be longer, and the molded product will have an advantage, because the product is directly docked by the nozzle of the injection molding machine, and the nozzle of the injection molding machine may be prolong, so it has obvious advantages when injecting deeper products;

5. It is conducive to hold pressure (feeding shrinkage), because the direct gate size is big and the process is short, the pressure in the pressure holding stage of the injection molding process is relatively small, which is very obvious to solve the issue of product shrinkage;

6. Conducive to product exhaust, this type of gate is generally located in the center of the product, and the molten plastic during injection is diffused and filled from the middle to the surroundings, so the air trapping problem of the product is very easy to solve.

Disadvantages:

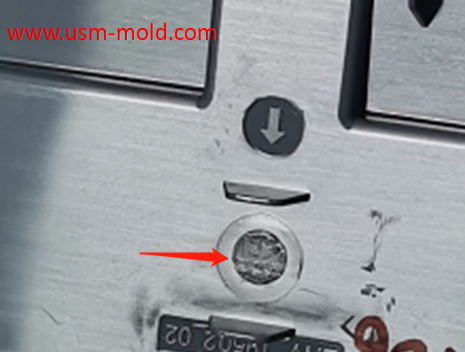

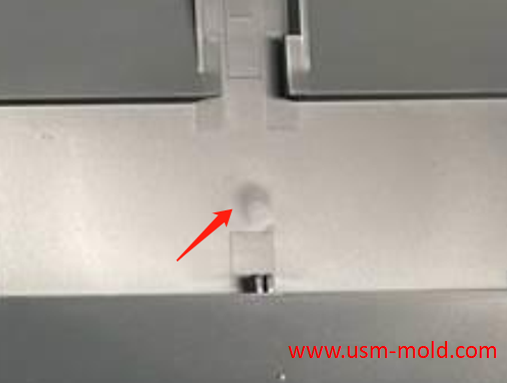

1. Gate marks will affect the appearance, because this gate is generally designed in the center of the product, there will be a mark after cutting the gate (as shown in picture 2), which is not suitable for products with high appearance requirements;

2. Flat and shallow products are prone to warpage and deformation, because this type of gate is generally in the center of the product, the pressure in the middle of the product is the largest during injection molding, and the pressure around it will be much less. Therefore, after the product pick up of the mold, due to the stress formed by the pressure difference, the product is easily warped deformation

3. The stress mark is big, the stress at the gate is also big, and stress marks will be formed on the back of the product (as shown in Figure 3), which will affect the appearance of the product.

4. Only one product can be formed at one time, because the center of the nozzle of the injection molding machine is facing the part gate, there is no conversion between the main runner and the sub runner, so only one product can be molded at a time.

We will share the side gate of the plastic mold gating system design in following news.

Plastic injection mold heating

Feb 16, 2022When the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition,...view

Five Major Steps of the Injection Mold Production Process

Dec 9, 2021Injection mold manufacturing can be roughly divided into the following steps: Process analysis of plastic products. Before the mold design, the designer should fully analyze and study whether the...view

USM Blogo Opening

Oct 27, 2021Hello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need. USM is a professional plastic injection mold and molding...view

What is Called Draft Angle?

Dec 29, 2021The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in picture 1....view

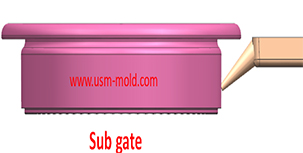

The sub gate of the plastic injection mold runner system

Jan 26, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view_20250317090912A017.jpg)

Several common process of water-assisted injection molding introduction

May 24, 2022According to the design of the injection molding machine and the casting system, the corresponding melt-returning process of water-assisted injection molding can be roughly divided into two types: the...view

English

English русский

русский