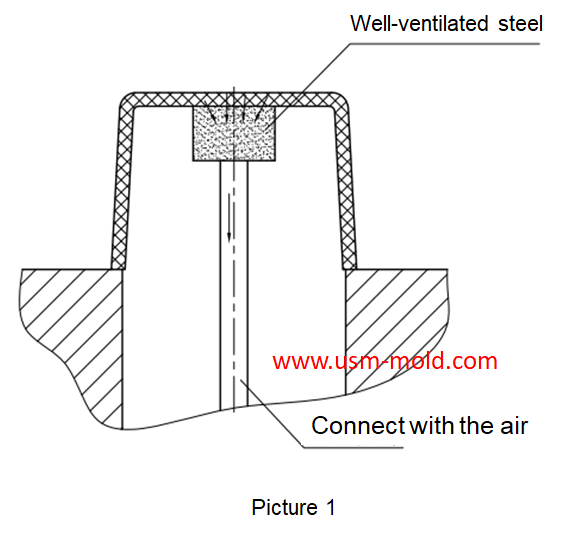

Well-ventilated steel of venting design for molded parts

Well-ventilated steel is a sintered alloy, iIt is a porous material sintered with spherical particle alloys, the pore size is 7-10μm and the strength is poor, but the texture is loose which allow the gas to pass through. Placing a piece of well-ventilated steel on the part that needs to be vented can make venting well. However, the diameter of the bottom vent hole should not be too big to prevent it from being squeezed and deformed by the cavity pressure, due to the low thermal conductivity of well-ventilated steelsteel, it cannot be overheated, otherwise, it is easy to cause decomposition products to block the pores.

Features of well-ventilated steel:

1. The density is small and the specific strength is big.

2. Good energy absorption.

3. Good vibration damping effect.

4. Large specific surface area, a quarter of the tissue is through holes.

5. Original hardness of well-ventilated steel: pre-hardened to 350~400HV (35~40HRC).

Well-ventilated steel characteristics:

1. Reduce injection pressure and pressure holding time;

2. Reduce and eliminate the internal stress of the molded parts to prevent the deformation and warpage of the product;

3. It can solve and alleviate the difficult forming issues due to gate deviation, uneven wall thickness, and thin wall plastic parts.

4. The gas generated by the high temperature of the molding material and the defects such as scorching, flow marks, material shortage, and part deformation caused by rapid pressure accumulation in the mold cavity can be fully resolved;

5. Improve molding production efficiency and save production costs, so put well-ventilated steel in suitable place of the injection mold, the injection issue caused by the gas can be completely eliminated, making the molding process much better.

Making the well-ventilated steel tips:

1. Use H7/m6 to fix the well-ventilated steel with mold;

2. Milling, grinding, polishing, knocking, etc. are not allowed on the surface of the well-ventilated steel to avoid clogging of the vent holes, only make EDM;

3. Choose to install the well-ventilated steel in a flat position to avoid cutting;

4. Exhaust slot or vent holes must be opened on the bottom surface of the well-ventilated steel, and connect with the air;

5. The use of well-ventilated steel for exhaust air will leave the shape of ventilating micropores on the surface of the product, so the ventilating element can only be installed on the non-critical surface;

6. In order to prevent clogging of the ventilation holes, regular maintenance of the exhaust components is required during forming and production;

7. Breathable steel exhaust is not suitable for resins that require high-pressure injection molding, such as PC, PC+ABS, etc.; high-pressure injection molding will cause damage to the exhaust components

Vacuum venting mold design for plastic molded parts

Mar 23, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

Reasons for making the exhaust system of the injection mold

Feb 28, 2022The gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in...view

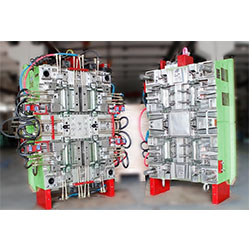

What is Plastic Injection Mold?

Dec 27, 2021The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and...view

Key points of gas-assisted injection molding process

Apr 20, 2022Gas injection parameters The gas-assisted control part is a device that controls the gas pressure in each stage, the gas-assisted parameters have only two values: gas injection time (seconds) and gas...view

Five Major Steps of the Injection Mold Production Process

Dec 9, 2021Injection mold manufacturing can be roughly divided into the following steps: Process analysis of plastic products. Before the mold design, the designer should fully analyze and study whether the...view

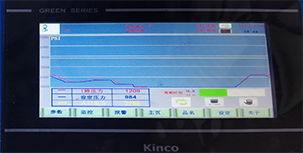

Controling method of plastic injection mold temperature

Feb 15, 2022Except for heat radiation and heat convection from the mold, most of the heat bring into the mold by the plastic needs to be taken out of the mold by the circulating heat transfer medium by heat...view

English

English русский

русский

_20250310164515A048.webp)