Factors affecting the cooling rate of parts by injection molding

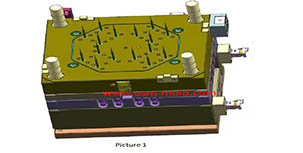

It should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature meet the requirements of the molding process. For plastics with high viscosity and poor fluidity, it is necessary to increase the heating temperature and add heating devices in case of difficult molding, due to the low mold temperature.

Importance of mold temperature control system

The mold temperature control and adjustment system affects the quality directly, molding and production efficiency of the part. If the surface temperature of the cavity and core is too high, it is easy to cause flash at the clamping part, and the wall thickness of the plastic part is easy to shrink; if the cavity temperature is too low, it is easy to have defects such as poor filling and insufficient strength at the weld line of the plastic part. If the surface temperature of the cavity and core is uneven, and the temperature difference is large, internal stress will be generated in the molded plastic part, resulting in warpage and deformation after molding, so the mold temperature control system is as important as the gating system, and it is also one of the key to mold design, the design of mold temperature control system should be very careful.

Whether the mold temperature is reasonable is related to the dimensional accuracy, appearance and internal quality of the molded plastic parts, as well as the production efficiency of the plastic parts, so it is an important job in the mold design. Different types of plastics have different temperature requirements for the mold, the general requirement is to make the mold temperature meet the requirements of the process conditions suitable for product molding, and the temperature control system can be adjusted to make the temperature on each part of the mold cavity and core basically the same, the mold temperature should be balanced and consistent in each molding cycle during production process for a long time.

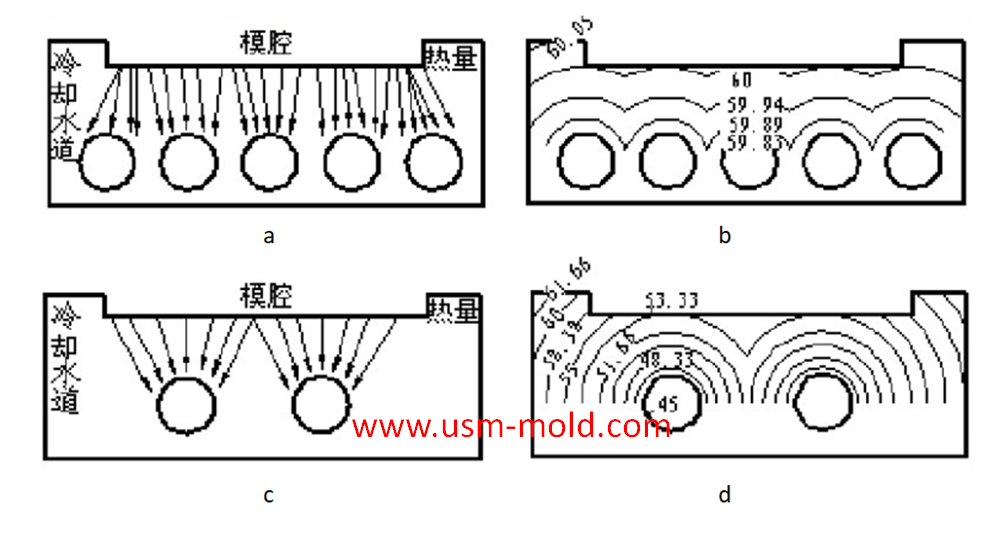

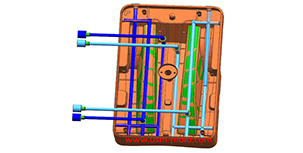

The influence of the cooling water gate of the mold temperature control system on the surface temperature of cavity and core side, the surface temperature of the cavity is relatively uneven and the change of 60~60.05 ℃ when 5 bigger cooling gate are used, it shows in following picture a and b, as shown in following picture C and d, the big temperature difference will cause uneven shrinkage, resulting in warpage and deformation.

The role of mold temperature control system

1. Improve molding performance and shorten molding cycle;

2. Stable part dimensional accuracy and prevent deformation;

3. Eliminate appearance defects and improve the surface quality of plastic parts;

4. Improve the mechanical and physical properties of the product.

Plastic injection mold runner system design

Jan 16, 2022The gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate...view

Plastic part ribs desigining

Jan 4, 2022The ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of the...view

The principle of mold temperature balance in plastic mold cooling system design

Feb 21, 2022The principle of mold temperature balance: 1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be...view

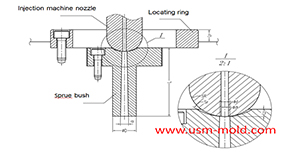

The main design points of the design of the plastic mold pouring system

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

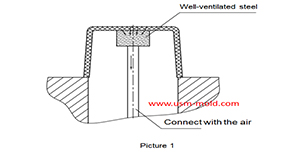

Well-ventilated steel of venting design for molded parts

Mar 14, 2022Well-ventilated steel is a sintered alloy, iIt is a porous material sintered with spherical particle alloys, the pore size is 7-10μm and the strength is poor, but the texture is loose which allow the...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

English

English русский

русский

_20250310164515A048.webp)