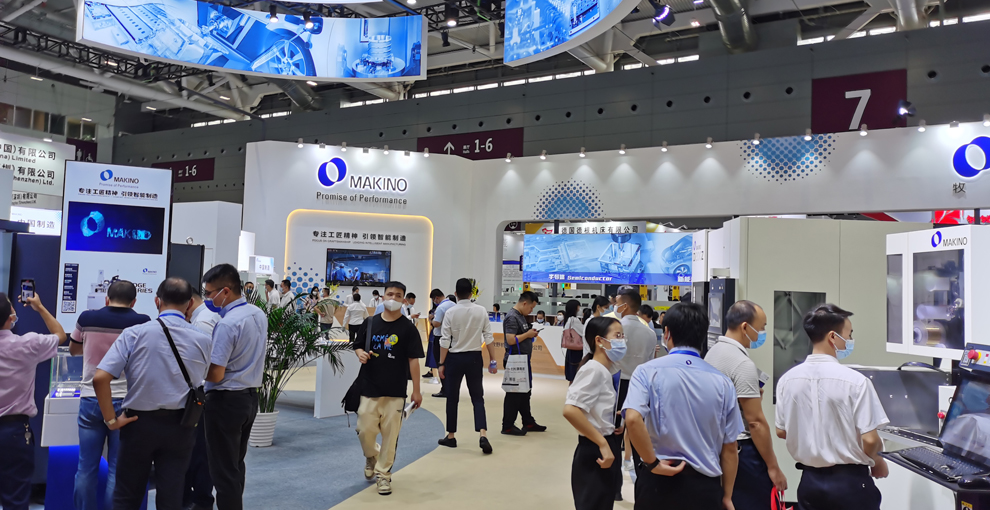

2022 Shenzhen Industrial Exhibition ITES Ended Successfully

The 2022 ITES Shenzhen International Industrial Manufacturing Technology and Equipment Exhibition and the 23rd Shenzhen International Machinery Manufacturing Exhibition were grandly opened in Shenzhen International Convention and Exhibition Center (Bao'an New Hall) on 15th Aug, and successfully concluded on 18th Aug. With the theme of "Gathering Wisdom, Creating Potential Energy, and Shaping High-Quality Ecology", this exhibition attracted more than 1,000 exhibitors, dozens of authoritative experts in the industry, representatives of industry organizations, and news media.

As a lighthouse exhibition for equipment manufacturing in South China, the 2021 ITES Shenzhen Industrial Exhibition lives up to its expectations, taking advantage of China's economic recovery, it presents an industry event where technology and thinking collide, bringing new development opportunities and promoting industrial progress together. At the ITES site, where the scale of the exhibition and the lineup of exhibitors have been upgraded unprecedentedly, governments also come to visit and give guidance; exhibitors show off their skills in an all-round way; nearly 1,000 industry associations and professional buyer groups come to discuss supply and demand and exchange technology; top streaming media going deep into the scene and reporting one after another... this not only demonstrates the huge industry influence of ITES Shenzhen Industrial Exhibition but also highly interprets the vitality and potential behind the strong growth momentum - the manufacturing market.

In 2022, ITES Shenzhen Industrial Exhibition will comprehensively display the entire metal processing industry chain - with high-end equipment as the core, the exhibition scope covers four major themes metal processing equipment, laser sheet metal equipment, industrial parts, and tools; professional automation equipment. As a supplement, it includes five major themes of factory intelligent logistics, assembly automation, robot applications, electronics and wiring harness equipment, and motion control.

As a member of the mold machining and manufacturing industry, USM keeps in touch with and learns from the advanced technology of the industry at any time, and also a loyal user of Makino processing equipment, so it is also fortunate to participate in this exhibition. Through the study of this exhibition, it is found that the mold processing industry is also undergoing a big change, from the original three-axis processing equipment to the four-axis and five-axis processing direction, from the previous multi-station multiple clamping processing to the transition to one-piece set-up is slowly becoming a reality. USM keeps exploring cutting-edge technologies, innovating process applications, accumulating experience, and improving technical levels with world-class advanced equipment manufacturers at all times, so as to keep the company abreast of the times and always maintain a leading position in the industry.

_20250317091113A018.jpg)

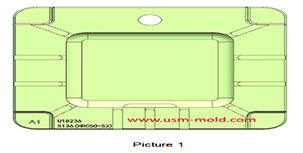

The basic points of designing gas-assisted injection molding

Apr 17, 20221. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel; 2. The gas channel should be arranged in...view

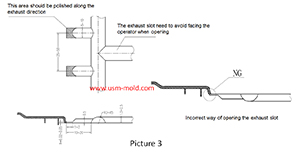

Venting of parting surface

Mar 7, 2022The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...view

Parting surface venting of runner system

Mar 10, 2022There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...view

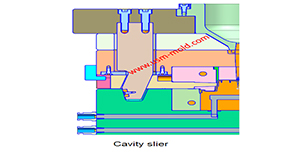

What is the side parting and core pulling mechanisms with their function?

May 31, 2022When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...view

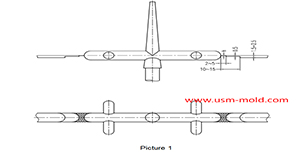

Banana gate of plastic injection mold runner system design

Feb 7, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Design standard of exhaust slot

Mar 3, 2022The exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...view

English

English русский

русский

_20250310164515A048.webp)