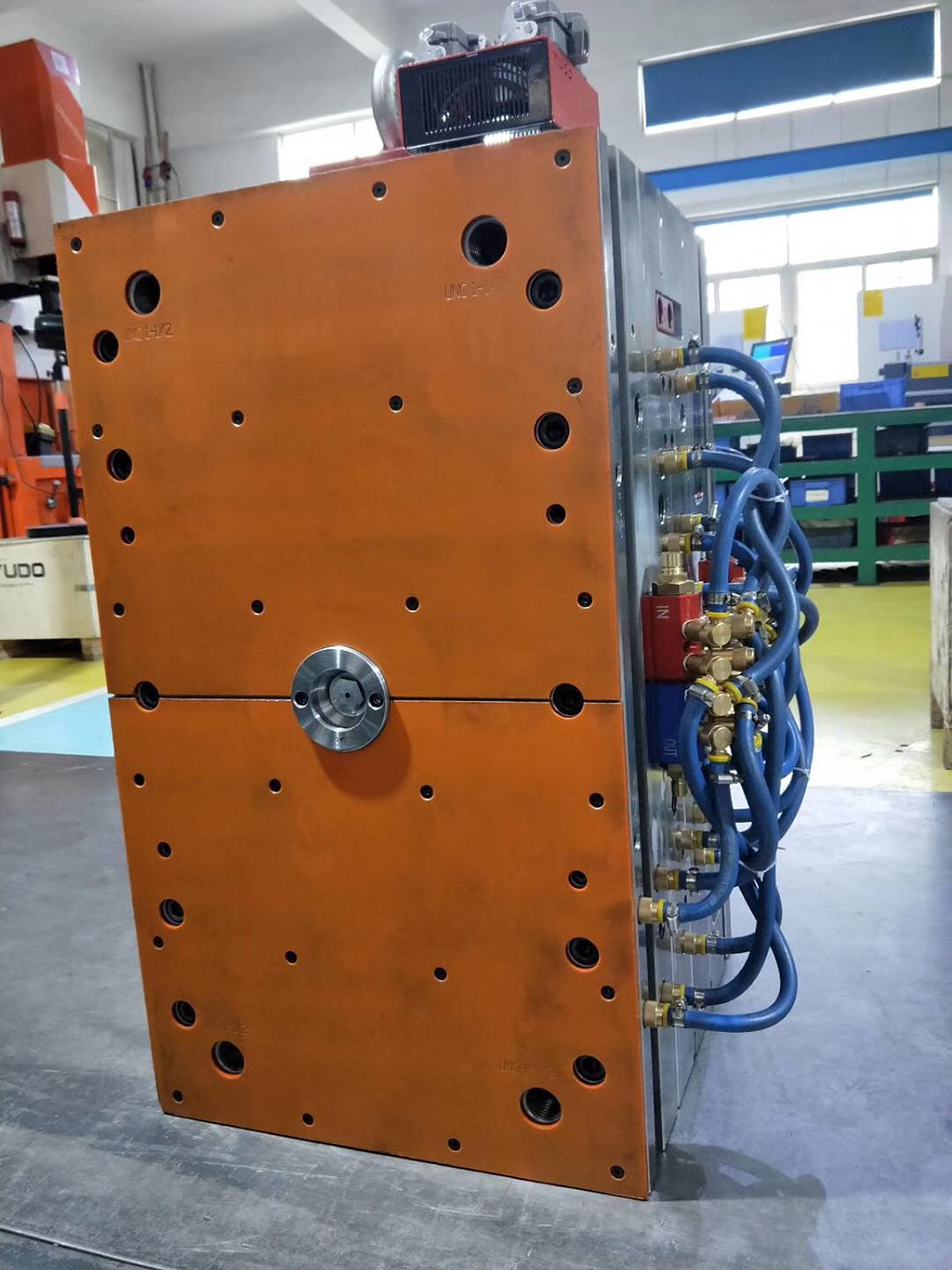

3 Precision Molds Are Ready To Ship Germany

After 2 months later, the 3 molds have been finished and ready to ship. From DFM report to mold design to manufacturing and T1 samples were provided in 6 weeks.

It is our honor to be the business partner of this German customer since April 2021, It is our honor to receive 2nd order from our customer. At the first time, the customer purchased 1 mold from us as a trial order, but after he received the T1 samples, he was very impressed with our engineering and service, and then start the following order.

The material is PC+ABS in V0 class which is easy to corrode mold, so we used the import mold steel by ASSAB, the cavity was made by HRC 50-52 heat treatment, and the core was made by HRC 50-52 heat treatment, the injection system was used hot runner by the direct gate of Yudo, non-standard mold base of LKM, the spare parts were all used by DME, we made the mold flow analysis before mold manufacturing to testing in advance, we found that the part would be about 0.4mm deformation, so the engineer made an adjustment and testing the temperature difference by cavity and core side, so the T1 samples had very good result when we finish the mold trial.

From "our hands" to "customer's hands", it takes incredible patience. Thanks to our hardworking, skilled and talented team, to realize a project from an idea to a finished product.

Side gate of plastic injection mold runner system design

Jan 23, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

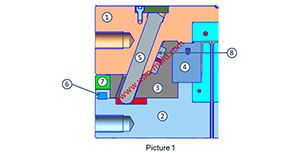

The design requirements of slider wear plate

Jan 2, 20241. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...view

Water assisted injection molding introduction

May 11, 2022Like the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic...view

Slider of side core pulling mechanisum assembling

Jul 21, 2022The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism. 1. Lateral forming...view

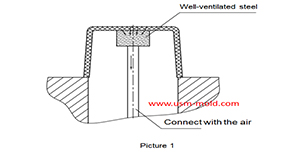

Well-ventilated steel of venting design for molded parts

Mar 14, 2022Well-ventilated steel is a sintered alloy, iIt is a porous material sintered with spherical particle alloys, the pore size is 7-10μm and the strength is poor, but the texture is loose which allow the...view

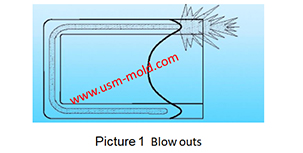

Gas-assisted injection molding product defects and solutions

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

English

English русский

русский

_20250310164515A048.webp)