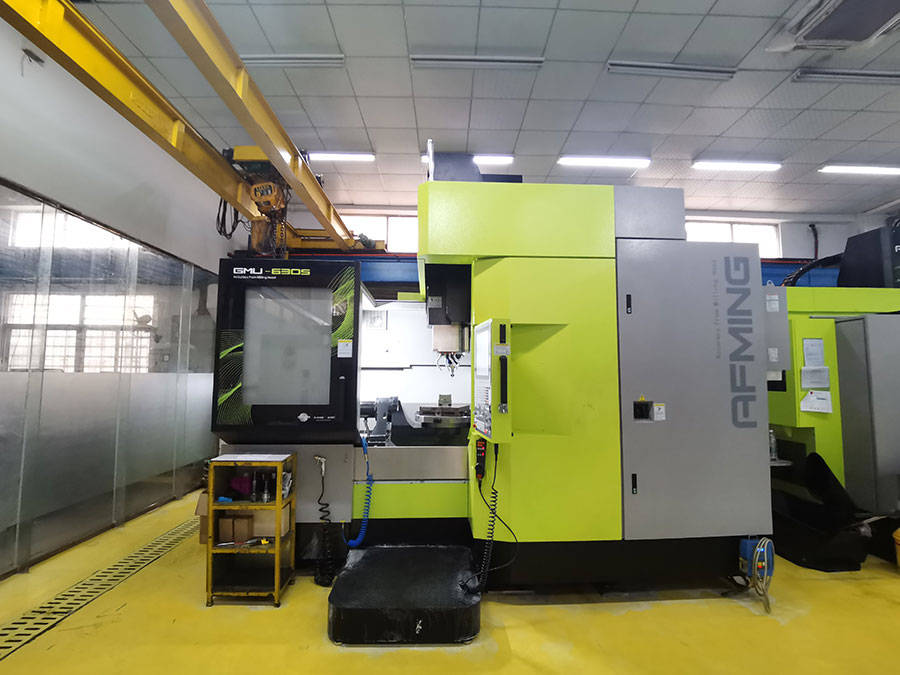

New Five-Axis CNC Machine Arrival

The new 5 axis CNC machining machine has arrived in our workshop on 6th Nov. 2021 and is now putting into use.

GMU-6350 type CNC machining machine

Working stroke (XYZ): 630*500*550

Maximum loading: 800kg

Machining accuracy: ±0.01mm

The rotation angle of centre worktable: 360 degree

Turning angle of centre worktable: 120 degree

Main working advantages:

1. It can process a continuous and smooth curve surface, and also can finish some parts which can not be processed by general three-axis CNC machine or are difficult to complete in one time, especially traditional three-axis machinings centres such as blades of aero engines and steam turbines, and propellers for ships, for parts that cannot be processed, the five-axis can be processed directly;

2. It can improve and control the processing accuracy and quality of curve surface;

3. Reduce clamping and changing appliques time and files ;

4. For the processing of deep cavities undercuts and small ribs on the mold, it can be processed by a five-axis machining centre to reduce electrical discharge and other processes directly, and improve the quality and efficiency of the mould.

Since USM was founded in 2011, USM has continuously improved the machine and equipment, from installation, adjustment, training of employees to putting into use, step by step to increase the production capacity and improve the quality. We always adhere to the needs of customers, and adjust the positioning of enterprises in the process of cooperation with customers, so as to achieve the goal of customer requirements, and constantly provide customers with more professional and better mold programs and services.

In the future, we will also strive to move forward, accumulate more than ten years of experience in the mold industry, and continue to create unique value for customers, USM is looking forward to providing quality service to our customers.

_20250317091113A018.jpg)

The basic points of designing gas-assisted injection molding

Apr 17, 20221. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel; 2. The gas channel should be arranged in...view

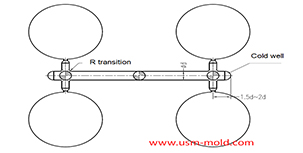

Key points of plastic injection mold runner system

Jan 12, 2022The sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...view

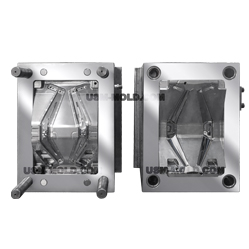

What is Plastic Injection Mold?

Dec 27, 2021The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and...view

Plastic injection mold runner system design points

Jan 9, 2022When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...view

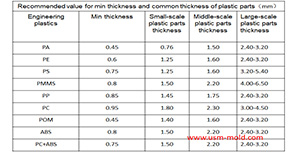

Design principles for wall thickness of plastic products

Jan 3, 2022The principles of wall thickness design for plastic parts are as follows: 1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking...view

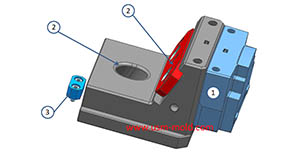

Slider designing tips 1

Aug 3, 20221. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially...view

English

English русский

русский