Video Of CNC Machining Processing By Dongguan International Machine Tool Exhibition In 2021

The 3rd China Machine Tool Purchasing Festival-DME Dongguan International Machine Tool Exhibition (hereinafter referred to as DME) was grandly closed at Guangdong Modern International Exhibition Center (Dongguan Houjie) on 13th Dec. 2021, as the key station of China Machinery Exhibition in South China, with the common expectation and support of manufacturing industry partners, the DME was successfully held on with 130,000 square meters, and finally came to a successful conclusion!

The scale of DME breaks through again: Guangdong Modern International Exhibition Center (Houjie Town, Dongguan City) has more than 1500+ exhibitors in 7 exhibition halls of 130,000 square meters manufacturing exhibition, exhibited 200+ explosive equipment, and held 16 professional conferences, focusing on CNC machine tools, development in many fields such as mold manufacturing and automation, insight into the development trend of the industry, and in-depth breakthroughs in the industrial pattern.

As a tool in the mold manufacturing industry, the development direction of high-efficiency processing, high-precision equipment, and automation is the goal pursued by enterprise, USM as a member of the mold industry, we are here to bring you a video of advanced CNC efficient processing, so many other people who also work in this industry but far away due to the epidemic can also feel the latest developments of the exhibition. The feed rate of this equipment in the machining process has surpassed the understanding of most mold partners while improving the cutting efficiency, this also places higher requirements on the rigidity and performance of the machine tool. As a mold company, USM also undertakes mold design, gas-assisted mold design and manufacturing, water-assisted mold manufacturing, two-color mold manufacturing and injection molding, full injection mold processing, CNC processing, CNC high-speed milling, and gas-assisted injection molding services.

It is the third DME, and it also brings a successful conclusion to the 2021 National Chain Exhibition of China Machinery Exhibition, it may have regrets but have more confidence in the future!

The 3rd DME ended smoothly, and this is also a new beginning!

China Machinery Exhibition-DME Dongguan International Machine Tool Exhibition will strive to achieve a higher value and higher efficiency manufacturing exhibition with Chinese characteristics!

Venting of parting surface

Mar 7, 2022The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...view

Gate position determination of plastic injection mold runner design system

Jan 17, 2022In the selection of gate location, the following issues should be paid attention to: 1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt...view

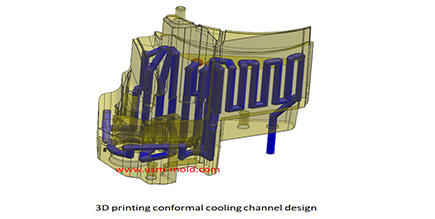

Design principle of plastic injection mold cooling system

Feb 13, 2022Design principle of cooling system In order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in...view

Water assisted injection molding introduction

May 11, 2022Like the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic...view

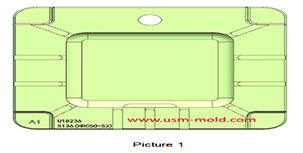

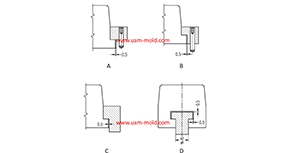

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

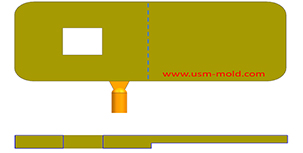

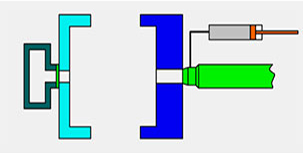

The difference between full shot and short shot of gas-assisted injection molding

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view

English

English русский

русский

_20250310164515A048.webp)