USM Purchased Two New Sodick Edm Equipments

USM purchased 2 new EDM Sodick equipment arrived a few months later, just finished the assembling and adjustment, we are very excited to see the processing soon with our new projects soon.

These 2 machines can make the processing 50% quicker and much more precise than normal EDM machines, especially for ribs processing, and also keep mold surface very well.

So that the processing surface can reach 0.35mm, and also make the radius in 0.01mm by EDM, surface highlight to achieve mirror effect and improve the mold roughness.

"Never-ending pursuit of technology excellence", we commit to excellent craftsmanship and close cooperation with industry partners.

Since now, USM is more and more confident to satisfy the higher surface requirements of the injection mold and molded products!

Plastic injection mold runner system design points

Jan 9, 2022When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...view

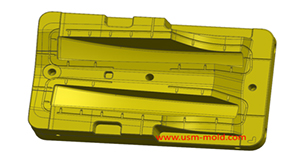

Slider designing tips 2

Nov 22, 20239. The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

The design principle of the exhaust slot

Mar 6, 2022The exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product...view

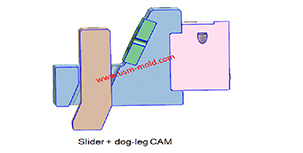

Classification of side parting and core pulling mechanism

Jul 17, 2022According to the structural characteristics of plastic moulding, the side core-pulling mechanisms are divided into the following six categories: 1. The side core-pulling mechanism of "slider + guide...view

Banana gate of plastic injection mold runner system design

Feb 7, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

English

English русский

русский