USM Purchased Two New Sodick Edm Equipments

USM purchased 2 new EDM Sodick equipment arrived a few months later, just finished the assembling and adjustment, we are very excited to see the processing soon with our new projects soon.

These 2 machines can make the processing 50% quicker and much more precise than normal EDM machines, especially for ribs processing, and also keep mold surface very well.

So that the processing surface can reach 0.35mm, and also make the radius in 0.01mm by EDM, surface highlight to achieve mirror effect and improve the mold roughness.

"Never-ending pursuit of technology excellence", we commit to excellent craftsmanship and close cooperation with industry partners.

Since now, USM is more and more confident to satisfy the higher surface requirements of the injection mold and molded products!

What is Called Draft Angle?

Dec 29, 2021The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in picture 1....view_20250317091113A018.jpg)

The basic points of designing gas-assisted injection molding

Apr 17, 20221. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel; 2. The gas channel should be arranged in...view

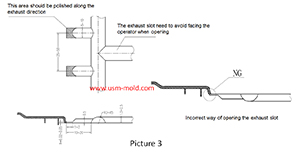

Design standard of exhaust slot

Mar 3, 2022The exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...view

Reasons for making the exhaust system of the injection mold

Feb 28, 2022The gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in...view

Five Major Steps of the Injection Mold Production Process

Dec 9, 2021Injection mold manufacturing can be roughly divided into the following steps: Process analysis of plastic products. Before the mold design, the designer should fully analyze and study whether the...view

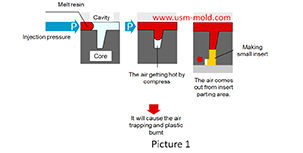

The main reasons for air trapping of plastic injecton mold

Mar 1, 2022During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...view

English

English русский

русский

_20250310164515A048.webp)