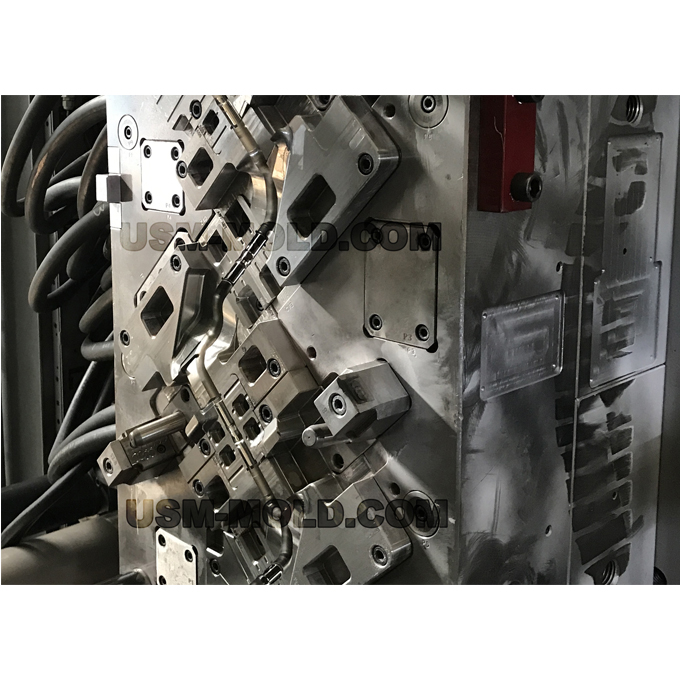

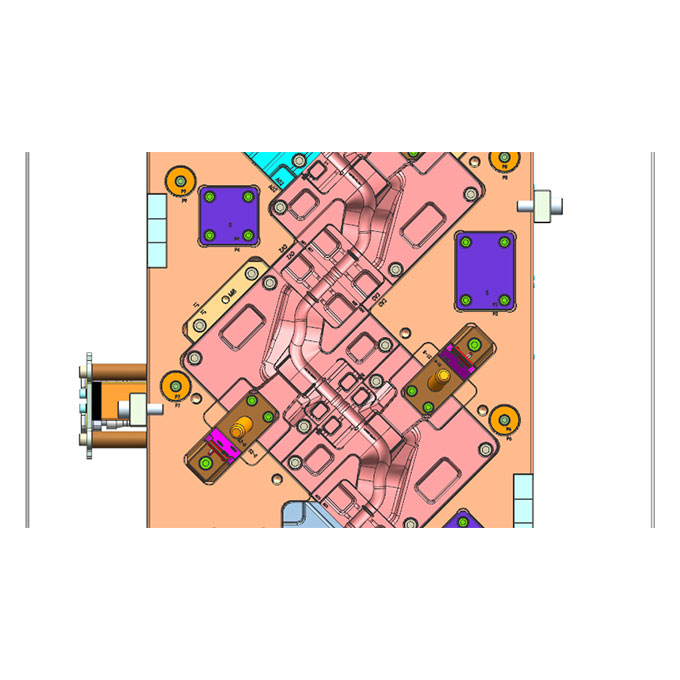

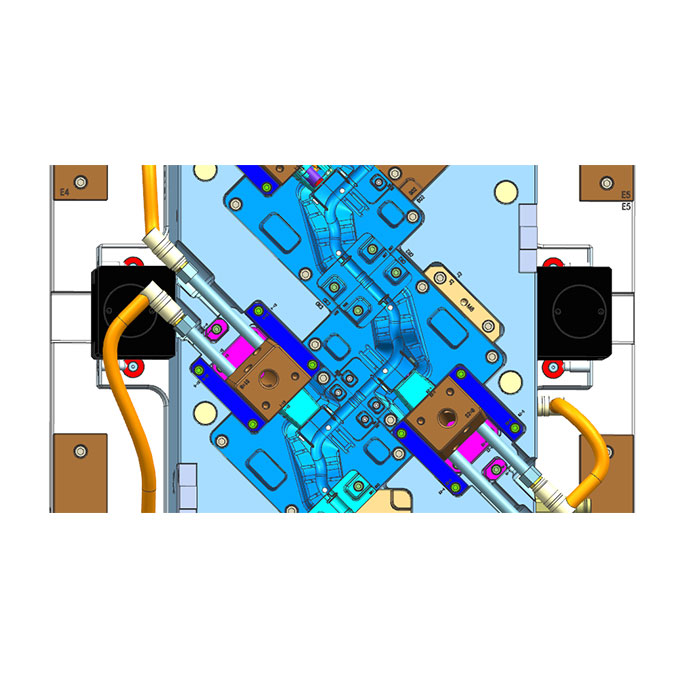

Water Assisted Injection Mould

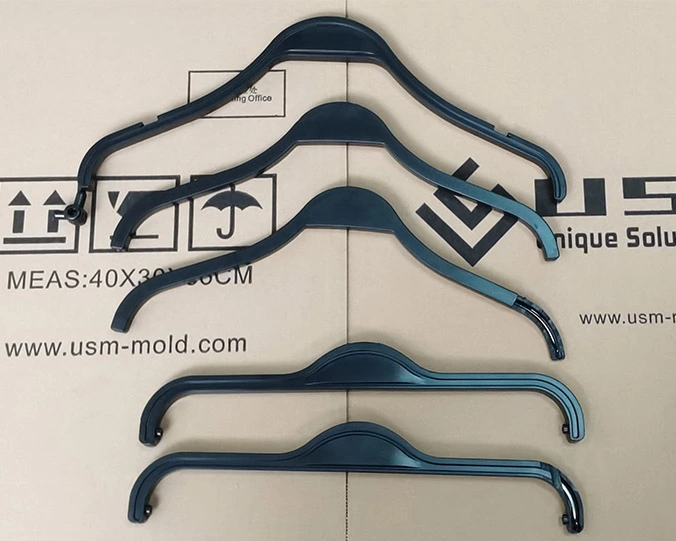

At this time, if the injection molding machine is allowed to inject the plastic to a certain position to stop the injection, and replace the melt into the mold with a certain pressure of the gas, the gas will also flow to the middle layer with the least flow resistance, so that with the help of gas pressure, it will push the melted plastic toward, and the melt injected into the cavity is inflated until the melt fills the whole cavity and core side, forming a plastic product with a complete hollow shape.

Don't Hesitate to Contact Us Now.

Related Gas & Water Assisted Injection Mold

English

English русский

русский