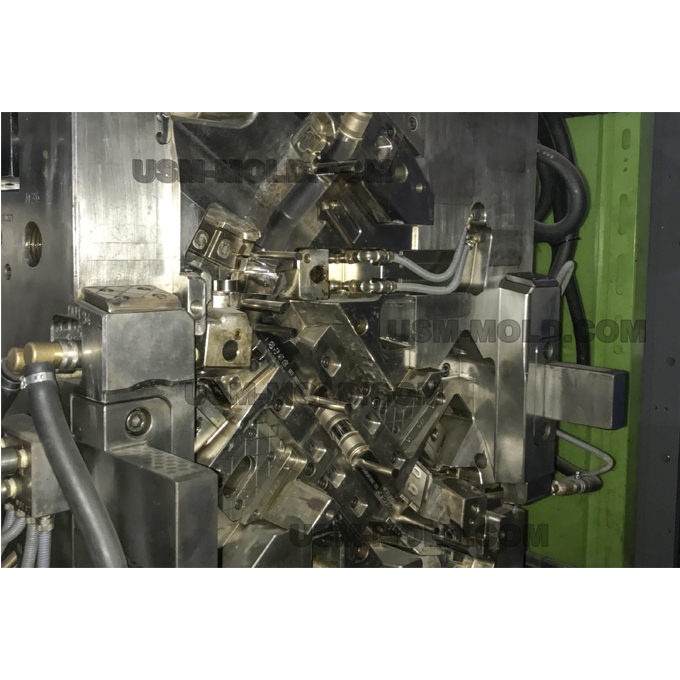

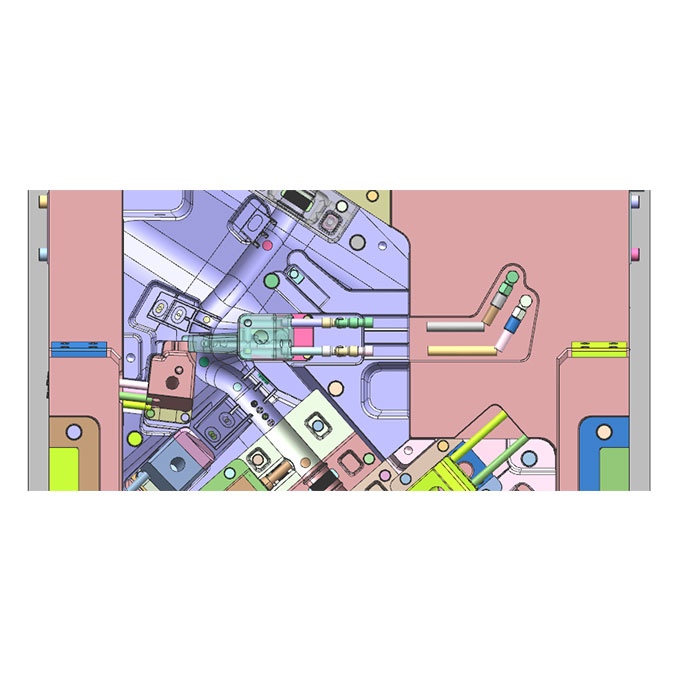

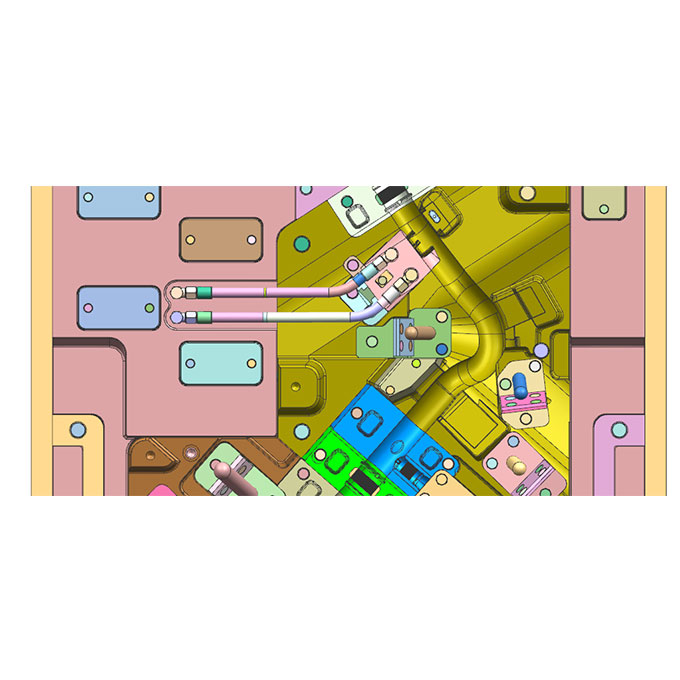

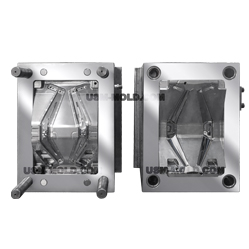

Automotive Water Intake Manifold Mould

Injecting gas through the nozzle is a typical method used in rod-shaped products, because this method does not require frequent changes to the mold and is versatile, but the disadvantage is that the nozzle needs to be modified and the single-use cost is high, and it lacks flexibility. The method of gas intake through the gas element needs to modify the mold, but it is flexible to use and can be used in combination with multiple processes. There is various gas injection mold, which can be divided into the main duct air intake, split runner air intake, cavity air intake, and so on. At present, the most commonly used is air needle air intake, the method is simple in design and convenient to install and disassemble, but it is easy to cause problems such as blockage and unblocked gas path.

English

English русский

русский