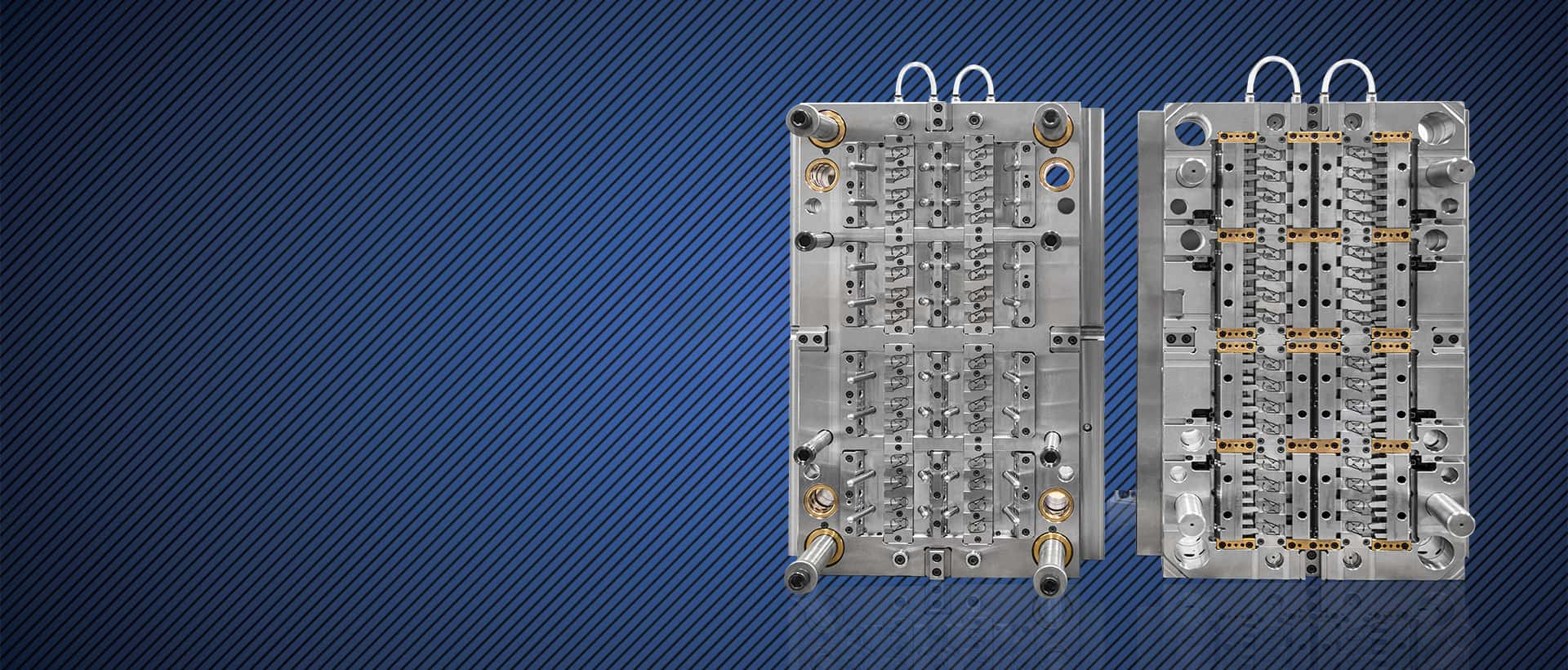

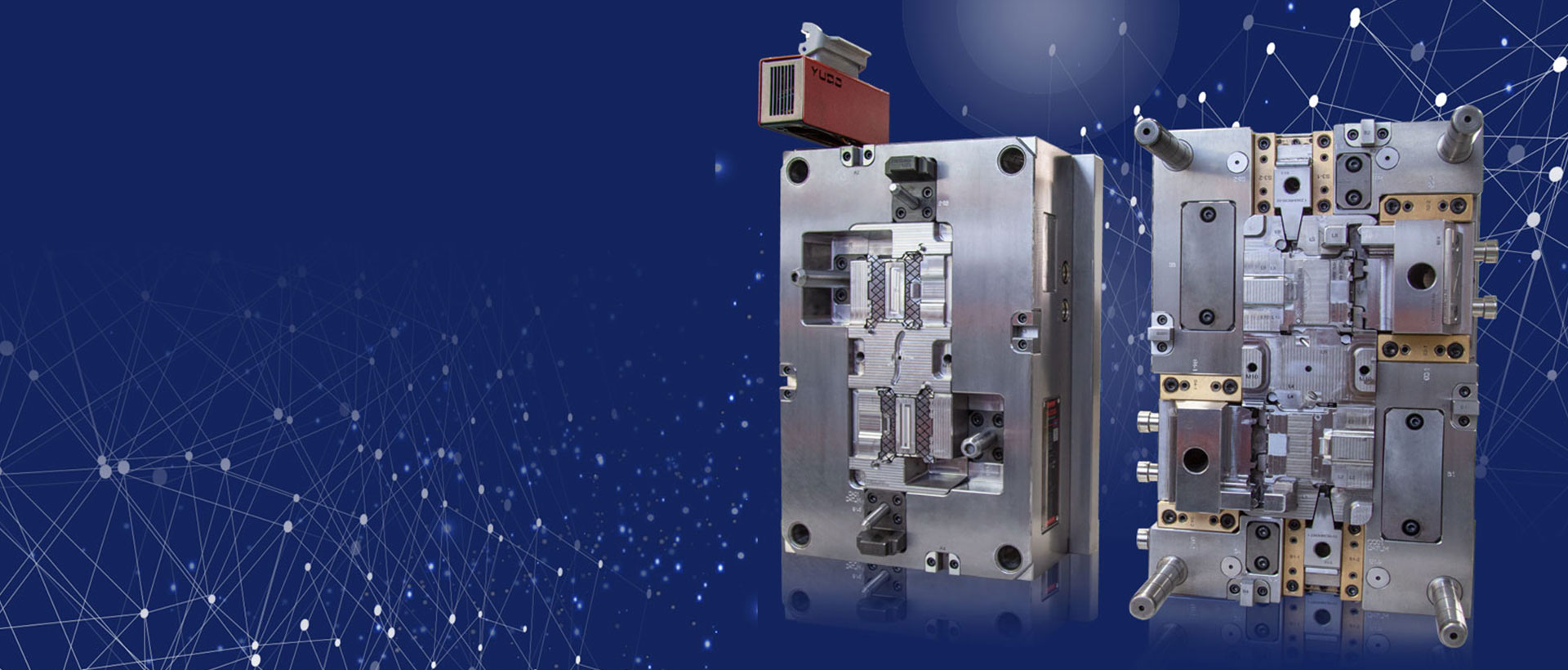

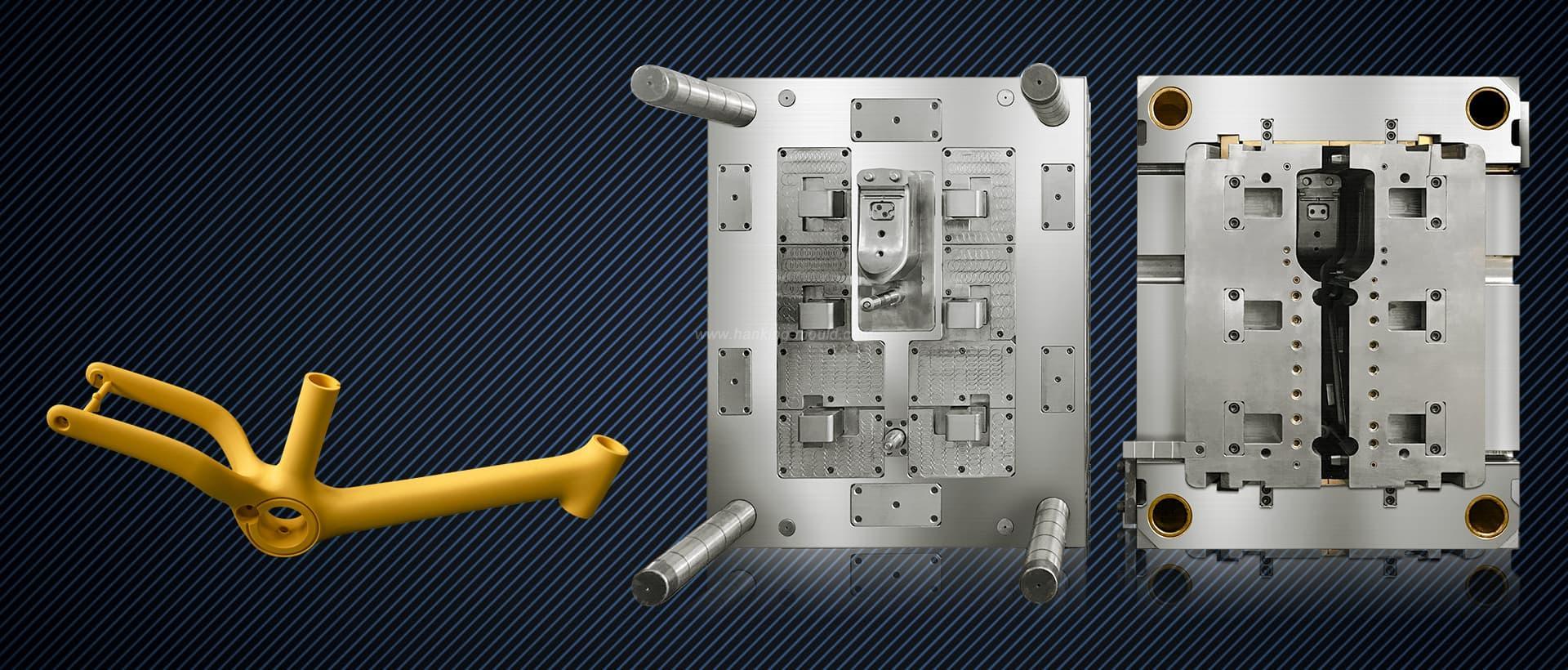

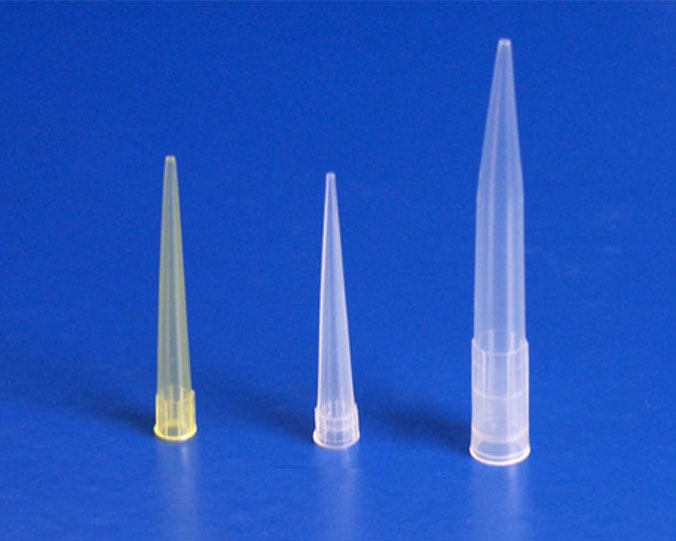

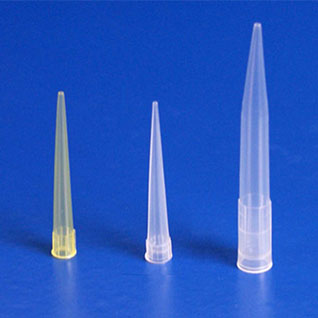

USM is one of the world's leading manufacturers of plastic injection mould and molded parts, medical molding & manufacturing. We have always pushed developments forward and set benchmarks in Automotive, High precision, and 2K molding, and other industrial parts.

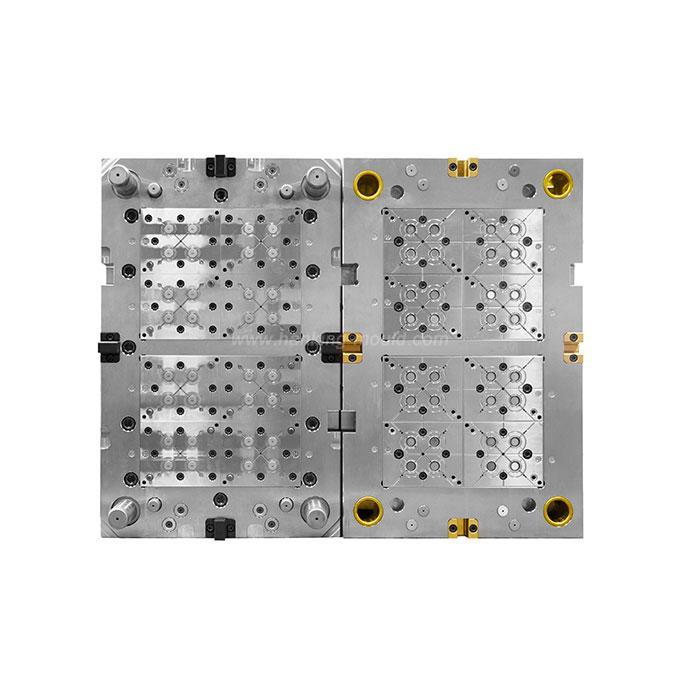

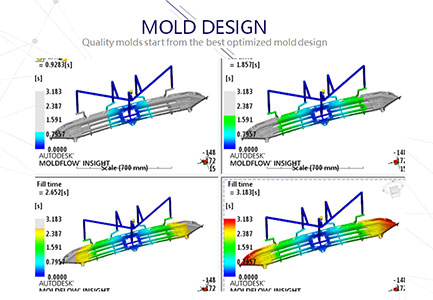

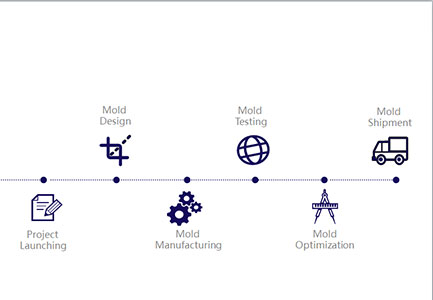

Project management, manufacturing, and engineering capabilities including project management solution, production design, development, mold and prototyping, material selection, manufacturing make USM does a good job in the mould industry.

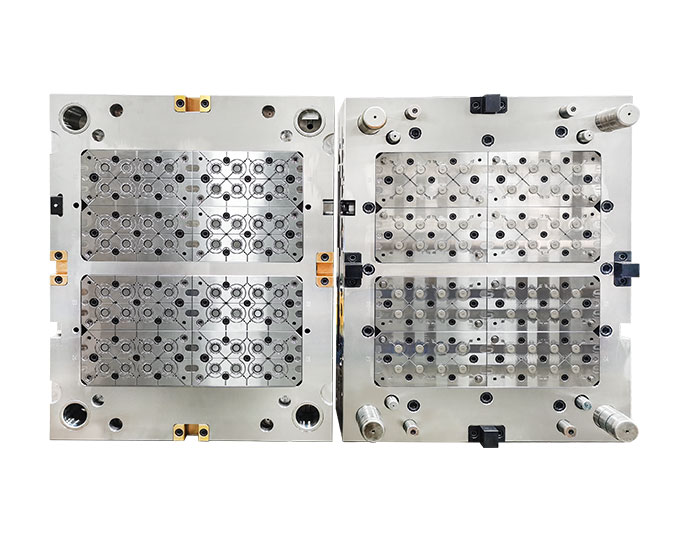

The ability to produce mold at the high international standard, strong engineering and design capability, aggressive lead time, and competitive price continues to be the success factor of USM.

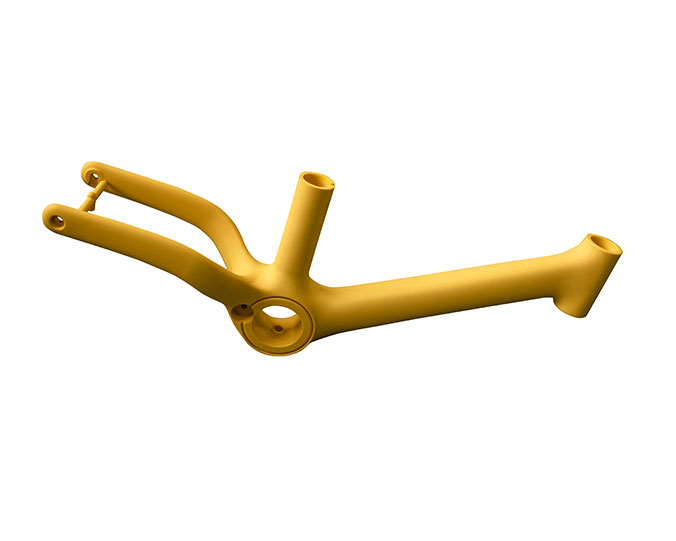

We welcome the most challenging of projects. Our expertise in complex geometries, technically challenging injection molding, gas assisted injection moulding and pre-deformation mold has set us apart with particular and advanced experience than 99% of other companies.

- USM makes a good job in mould industry

Project management, manufacturing and engineering capabilities including project management solution, production design, development, mould and prototyping, material selection, manufacturing.

- Success factors of USM

The ability to produce mold at the high international standard, strong engineering and design capability, aggressive lead time and competitive price.

- Leading manufacturers of plastic injection mould and molded parts.

We have always pushed developments forward and set benchmarks in Automotive, High precision and 2K molding and other industrial parts.

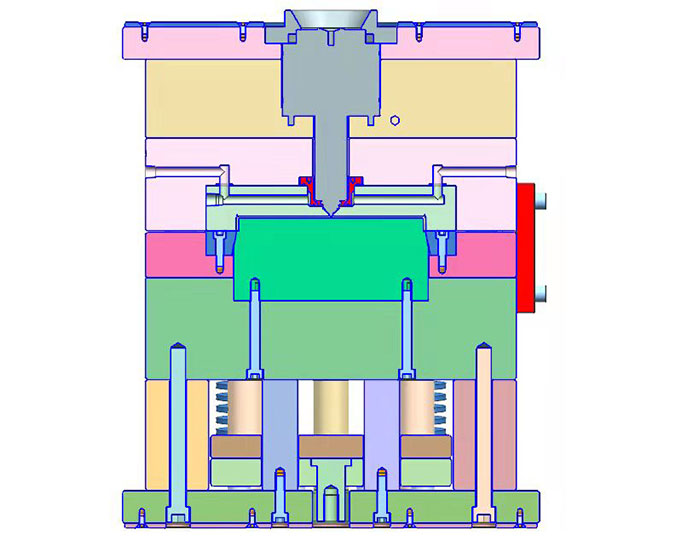

- The angle pin is a common part of the drive slider, and the fixing and installation methods as following: 1. Pass through the mold plate directly and press the angle pin with the top plate to fix it,...

- Processing size: 1. ØD2=ØD+2 2. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2) Spring length calculation: (refer to picture 1 for length calculation)...

- 1. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...

English

English русский

русский

_20250301164605A009.jpg)