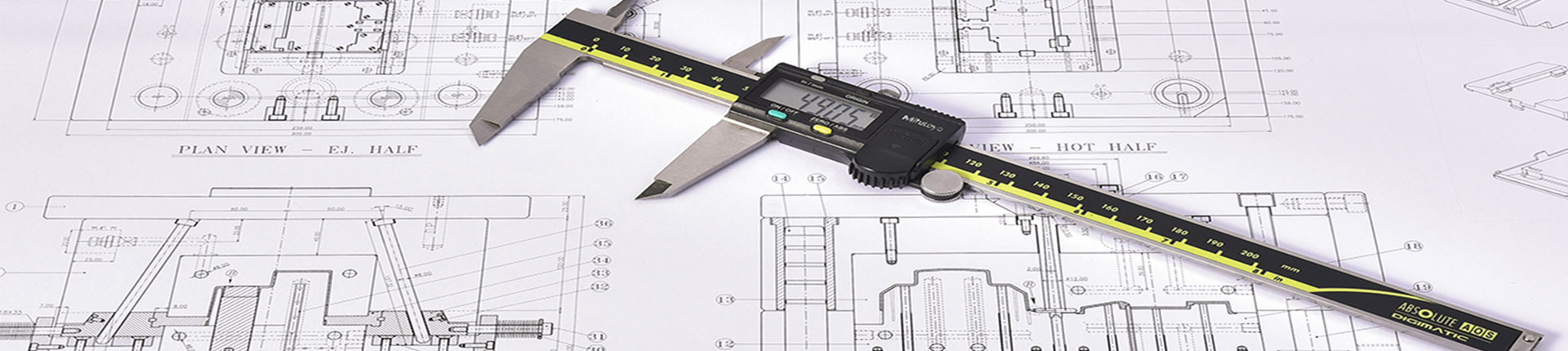

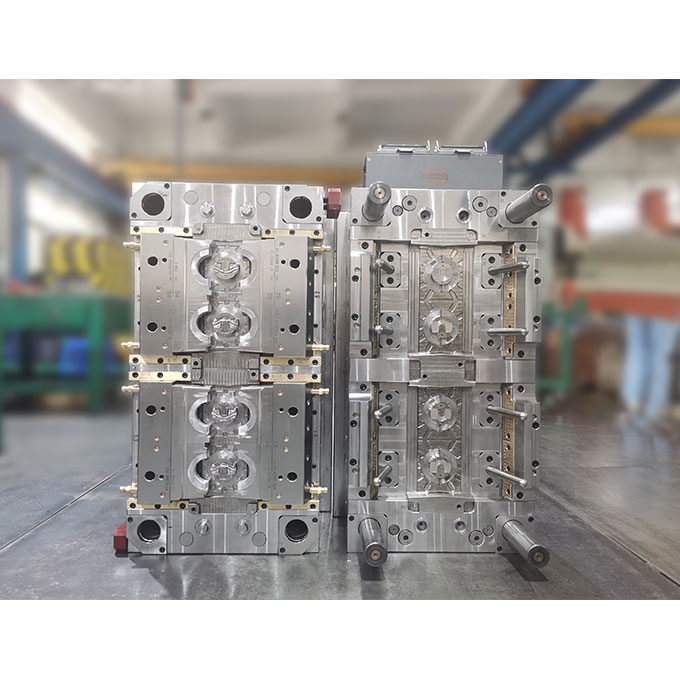

Switch Cover Injection Mold

It is not suitable for bare wire use in a vacuum, sulfur-containing, carbon-containing atmosphere, and an alternating redox atmosphere; when the oxygen partial pressure is low, the chromium in the nickel-chromium electrode will be preferentially oxidized, causing a great change in the thermoelectric potential, but metal gas has little effect on it, so metal protection tubes are mostly used.

USM Switch Cover Injection Mold Advantages

1. Reduce injection pressure: Since the hot runner is an extension of the injection machine barrel, there is no injection pressure lost on the cold runner. and also the pressure will be lower than the cold runner, which will be better for the injection machine and prolong mold life;

2. Realizing for automatic production: the part will be produced directly after injection without cutting gate and other processes, so it is easy to make automatic production;

3. Improve product quality: Since the hot runner can use a valve gate to control sequence, especially for big parts which will be used several valve gates, there will be no welding mark on the part surface.

English

English русский

русский

_20250311083139A052.webp)