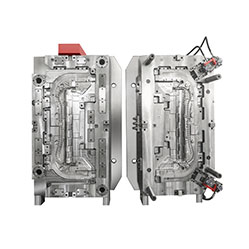

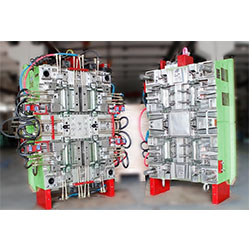

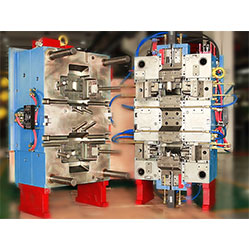

Pre-deformation Mold

When the plastic material rushes into the mold cavity, it loses heat due to heat conduction, and the melted plastic will freeze and solidify, therefore, for complex or large products, high mold temperature is usually used for filling, the purpose is to reduce the injection molding conditions, the stress is also conducive to debugging product deformation and shrinkage. However, high mold temperature will produce excessive oil stains, and molds with poor precision are prone to burrs.

PRE-DEFORMATION MOLD TYPES

The main reasons to cause the plastic parts are warpage and deformation

1. The uneven wall thickness of each part of the plastic product deforms.

Usually, the main part of the product is thicker and the ribs are thin, when the plastic parts are cooled, there are still uncondensed parts in the middle of the main body after the ribs are completely cooled, the continued cooling of the main body will inevitably cause the plastic parts to deform in the opposite direction to the ribs.

2. Uneven cooling of the mold cavity and core causes deformation. In the injection molding process of plastic products, if the temperature of the mold cavity core is inconsistent, it will also cause product deformation, the usual situation is that the side with high temperature shrinks, and the deformation is also warped to the side with high temperature.

3. Various stresses at part angles are deformed. One is that the wall thickness at the angle is thicker, and it is generally cooled at the end; the other is that the molecules in the corner are elongated during unique injection molding systems of the plastic part, these two factors will cause product deformation.

4. The plastic part deforms when it is ejected. When the plastic parts are formed, the shrinkage of the product will produce a larger holding force, especially for deep cavity parts, when the plastic part is ejected, because the plastic part is not completely cooled, if the external force on the ejection exceeds the elastic limit of the plastic part, it will cause the product to deform in the ejecting direction.

5. The imbalance of the product's filling feeding leads to inconsistent internal stress of the product, choose the right gate numbers, but also pay attention to the balance of each gate and the shape and position of each gate.

The influence of injection molding process parameters on deformation

1. Mold temperature:

When the temperature of the mold cavity and core side is very different, it will cause the mold to freeze and not open, the higher the mold temperature, the bigger the shrinkage and the greater the deformation, the temperature difference between the inner and outer surfaces of the product will cause thermal stress and thermal deformation, and the inconsistent temperature of different areas of the mold will cause uneven shrinkage of the product and warp deformation.

2. Melt temperature:

Low melt temperature is not conducive to injection molding, the decrease in melt viscosity will increase the cooling rate of the melt, lead to poor plasticization of the melt and increase the difficulty of the process; high melt temperature is good for molding, which can reduce the viscosity of the melt and reduce the orientation stress, but it cannot too high which will cause thermal degradation.

3. Injection pressure:

Injection pressure is to overcome the existence of resistance, in injection molding, the appropriate injection pressure should be suitable, and the standard is the filling will be the same after the speed is added. High injection pressure will influence the stress pressure for melt plastic during injection, so the smaller injection pressure is, the better for protecting the mold and equipment, but if it is too small which will cause unfull filling.

4. Holding time:

The holding time has a big effect on the size and elastic deformation of the product, when the melt is injected from the screw into the mold cavity, it will contract cold, the function of holding pressure is to make up for the space left by the injection.

The holding time is to ensure that there are no quality issues such as shrinkage marks on the part surface and reduce the holding pressure as much as possible, excessive holding pressure will increase the internal stress caused by the solution on the mold cavity and the product.

5. Holding pressure:

Excessive holding pressure causes excessive internal stress of the product, resulting in product stress cracking and burrs, too small holding pressure will cause product shrinkage, and the holding pressure controls the amount of material fed.

It has a big effect on the shrinkage and deformation of the product, mainly to make up for the remaining mold cavity space during injection filling.

6. Injection speed:

Multi-stage injection speed should be used: slow-fast-slow, the injection speed is fast, the heat of the melt can be maintained, the viscosity will be reduced, and it can flow farther, but if the injection speed is too fast, the gas in the column cavity will not be discharged.

7. Injection position:

In the case of normal process parameters, the injection position is filled to 90% of the product and then transferred to holding pressure, it is not unrelated to the shrinkage of the product and the warpage deformation, under unusual circumstances, it may be due to improper parameter adjustment, too much material causes warping and deformation.

8. Cooling time:

The cooling time is insufficient, when the product is demolded, the thrust generated by the ejector pin acts on the surface that is not cold-solidified, which causes the product to deform. If the cooling time is too long, the hot melt is injected into the cold mold cavity, and the melt shrinks and wraps the mold core when cold, resulting in an increase in the demolding force.

English

English русский

русский