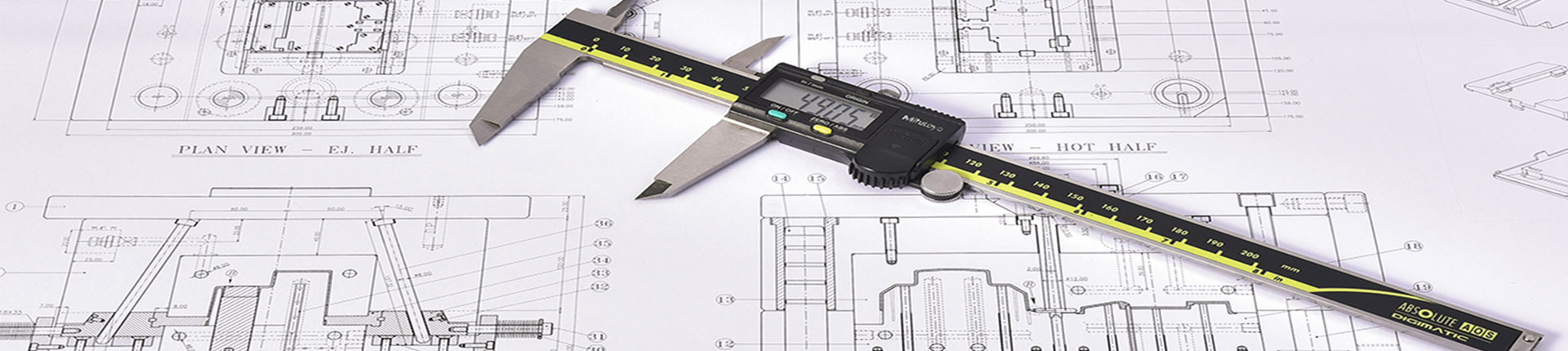

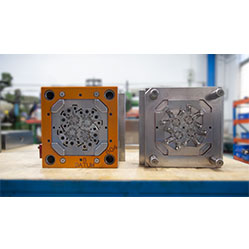

Plastic Insert Mold

Using the combination of resin insulation and metal conductivity particularly, the molded parts can meet the basic functions of electrical products. The pre-molding combination of multiple inserts makes the post-engineering of product unit combination more rational. Insert products are not limited to metals, but also cloth, paper, wires, plastics, glass, wood, coils, electrical parts, etc.

The Main Issues for Making Insert Molding

1. Flash: it will have flashes where the radius of insert sealing area, the radius is not accuracy like the drawing after insert bent, it causes flashes on assembling gap area, the other one will be in the big threaded hole;

2. The plastic with insert fit is not enough, the insert will be injected with plastic together and will cause the connection not good, then the part surface and function defects, we could improve this issue by adding connection place for plastic and insert.

3. The complex issue is deformation, the plastic will be cooler after contacting with insert, but it will cause pressure is not the same and influence part deformation, due to the insert can not shrink, it will need to make different ways to solve it, we normally consider that the plastic with insert fit whether it is enough, then check the cooling gate layout whether it is ok because the different temperature will also cause the shrink. Another way will be to change the material to test and modify the injection gate and quantity. the first 2 solutions are modified on mold, and the last 2 solutions are from initial which are more useful but the testing cost is very high.

English

English русский

русский