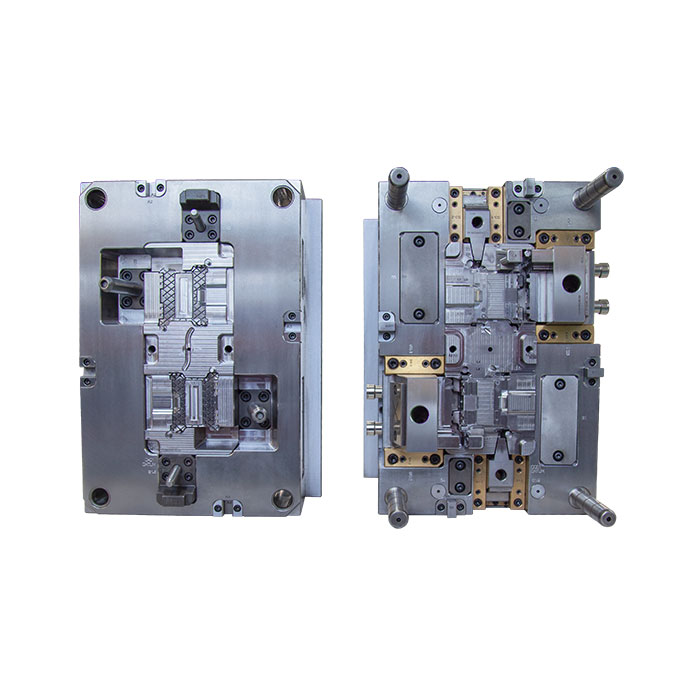

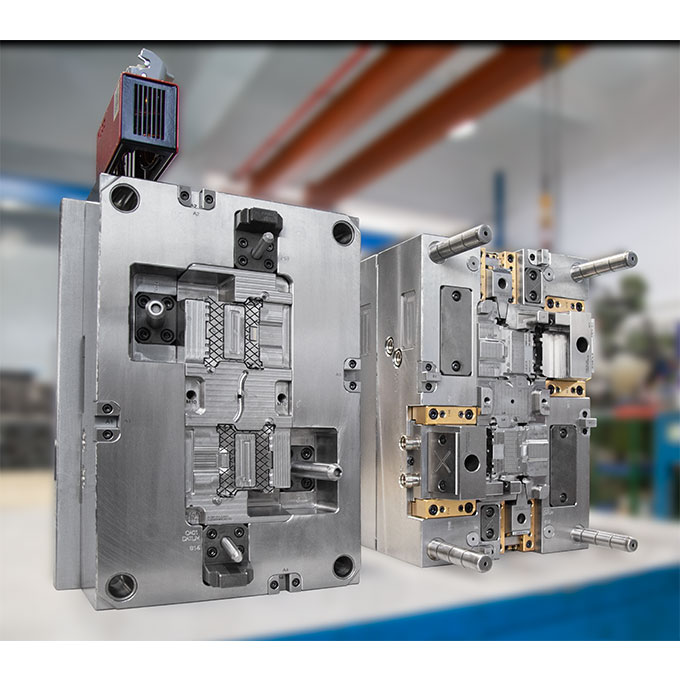

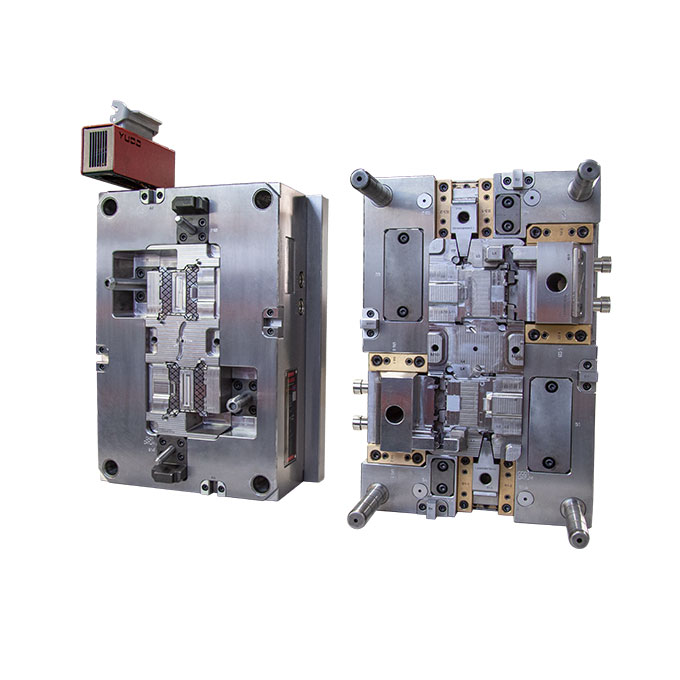

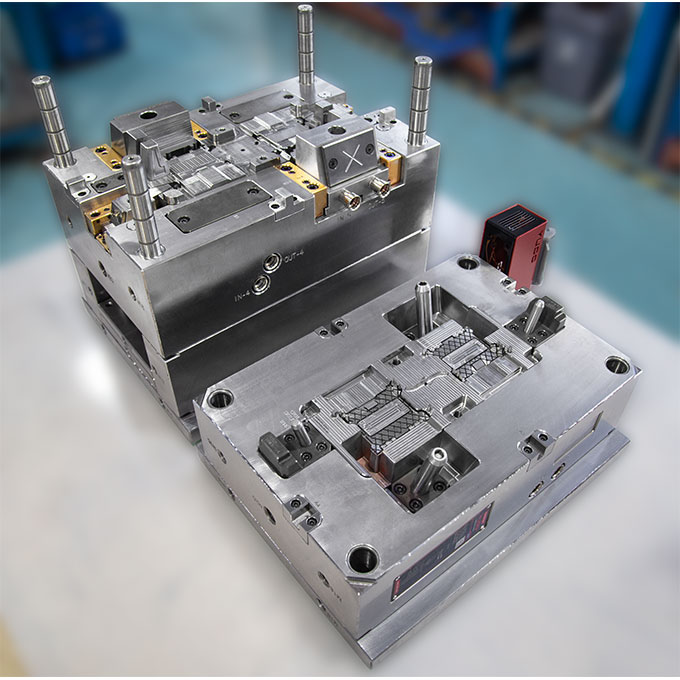

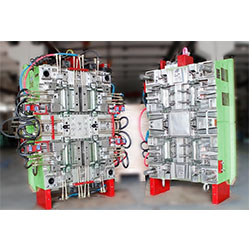

PA66 GF30 Car Parts Plastic Injection Mold

If you want to get the product is straight, your mold design and mold processing are also made straight, but there will be a bent product, deformed or the product size is out tolerance, they were caused by material, temperature, shrinkage, and injection molding process after the product cooling completely so that we will make the original straight mold into the opposite direction to the deformed product through design analysis and empirical compensation during mold design, then the product will become curved at the beginning, but the product will become straight and in good tolerance after natural cooling. This technique is called mold pre-deformation technology

Don't Hesitate to Contact Us Now.

English

English русский

русский