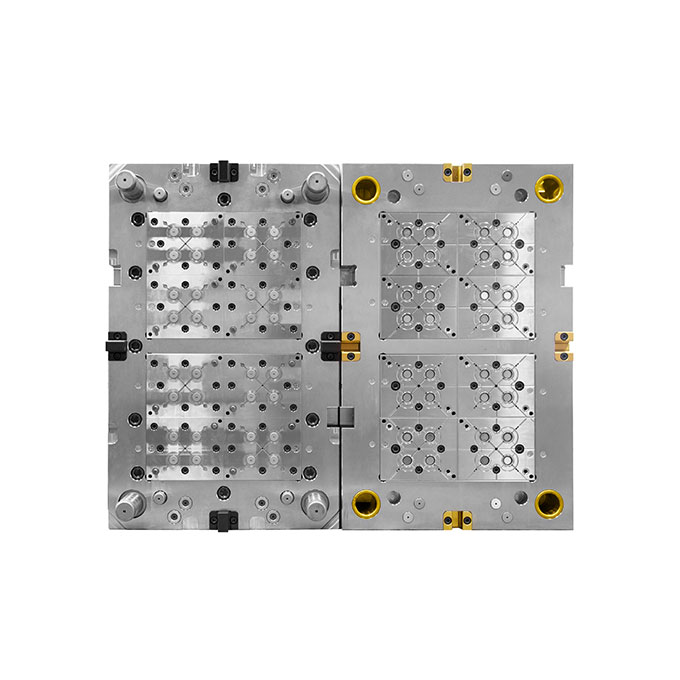

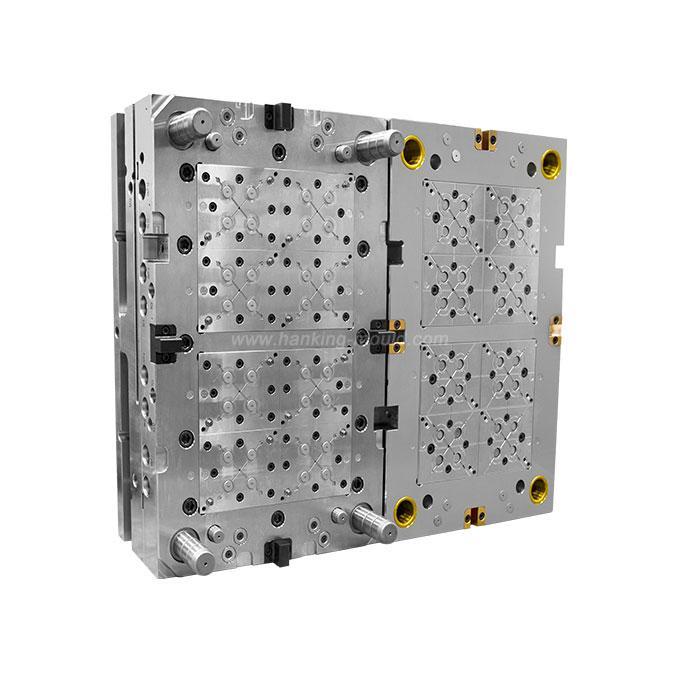

Multi Cavity Medical Mold

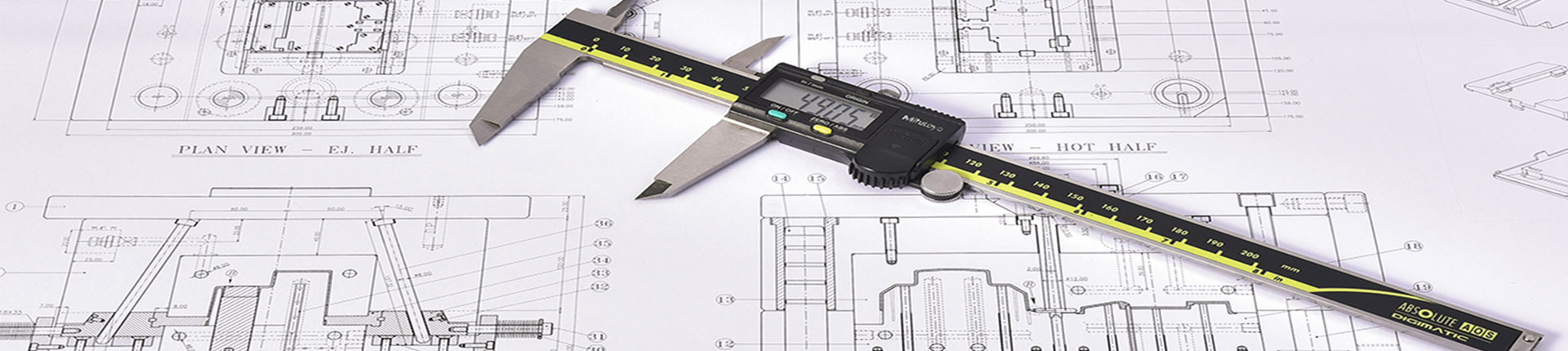

USM is an ISO9001:2015 certified mold and injection molding factory, with over 15 years of professional experience and advanced equipment, we've got many successful cases in multi-cavity medical molds, there are 10 engineers could assist our customers to develop from part design in order to reduce the time and win the market in the shortest time.

Multi Cavity Medical Mold Characteristics

1. Good physical and mechanical properties, which can meet the requirements of physiological function and use environment;

2. Medical injection molds can withstand the sterilization process without affecting its biological and mechanical properties;

3. Good forming performance, easy to process into various shapes, and low cost;

4. The material is medical grade, with low content of heavy metals, and low content of solubles and solubles.

English

English русский

русский