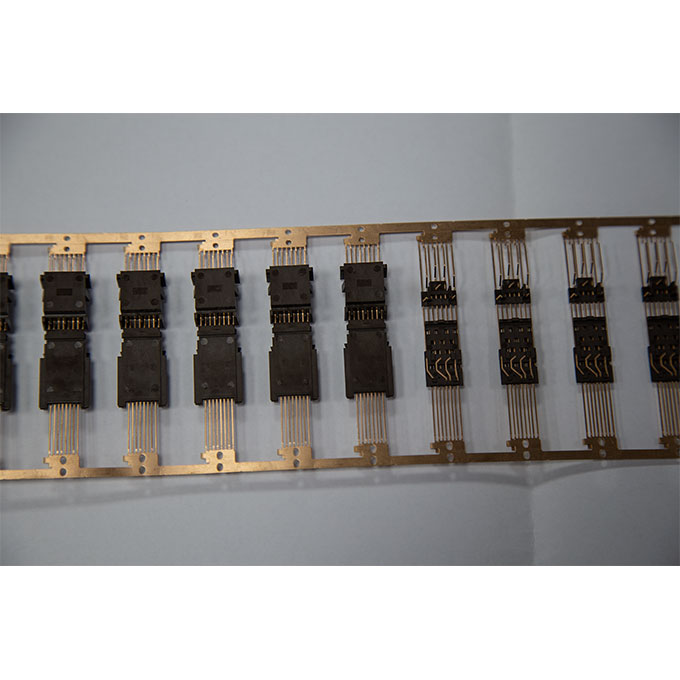

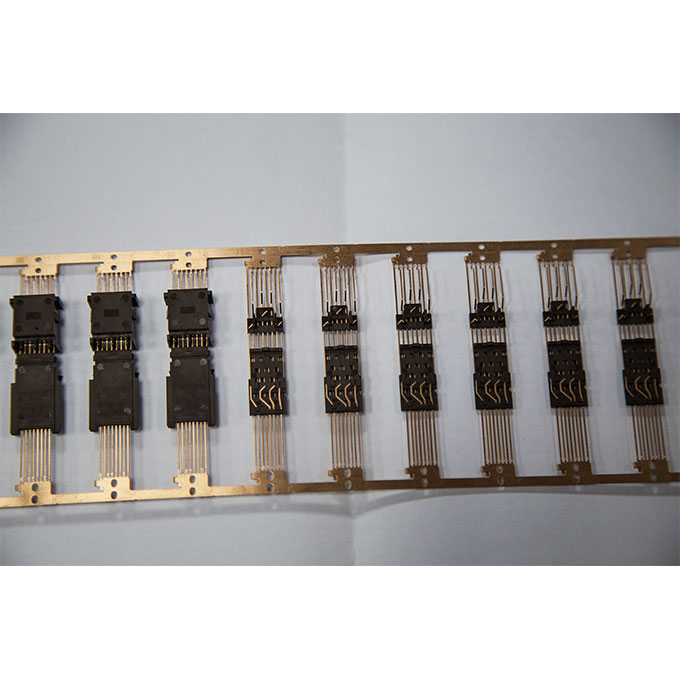

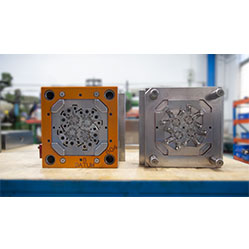

Metal Insert Mold

Choosing suitable material and molding conditions, not only for products that are easily deformed and damaged (such as glass, coils, electrical parts, etc.), can also be sealed and fixed by material. Choosing a suitable mold structure, the insert product can also be inserted into the plastic material. With the combination of the vertical injection molding machine, manipulator, and insert part aligning device, most of the insert molding engineering can realize automatic production. After the insert is molded, it can also be made into parts with hollow grooves after core hole processing.

Notes Need Attention When Making Metal Insert Part

1. In order to improve the connection firmness of the metal insert and the plastic part, the insert and the plastic part are tightly combined, and the surface of the insert should be knurled or processed with grooves to increase friction force, the insert is not easy to pull out and rotate.

2. The connecting part of the plastic part and the insert should have a suitable thickness to improve the connection strength of the two connecting parts, the selection of the thickness value should be determined according to the properties of the plastic and the shape of the insert, or refer to the empirical value in the table below.

3. The threaded fixing part of the insert and the mold should adopt the H9/f9 threaded fit to avoid melt plastic from entering the non-plastic end of the insert, if not connected with threaded, the H8/h7 sliding fit should be adopted; the insert can be made convex, this can not only block the melted plastic but also increase the stability of the insert and the mold.

4. The parts inserted into the plastic part should be inverted into a circular arc shape to prevent stress concentration in the plastic parts.

5. The length of the insert embedded in the plastic part diameter should not be bigger than 2 times.

6. In order to avoid the insert from damaging the mold cavity, it should be noted that the height of the insert is slightly smaller than the height of the molding cavity of the plastic part, and the difference is about 0.05mm.

7. In order to prevent the metal insert from being pulled out, a ring groove can be placed in the middle of the insert.

8. For externally threaded inserts, a non-threaded area should be provided to prevent molten material from penetrating into the mold.

English

English русский

русский