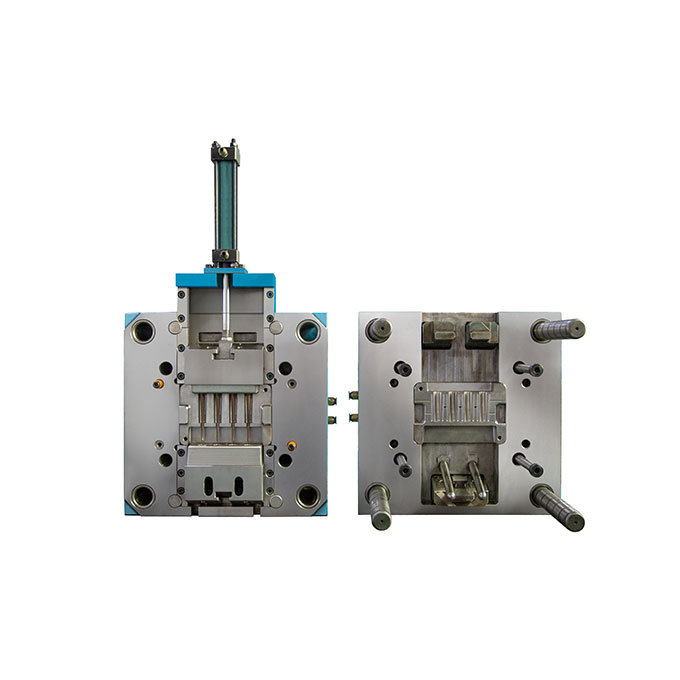

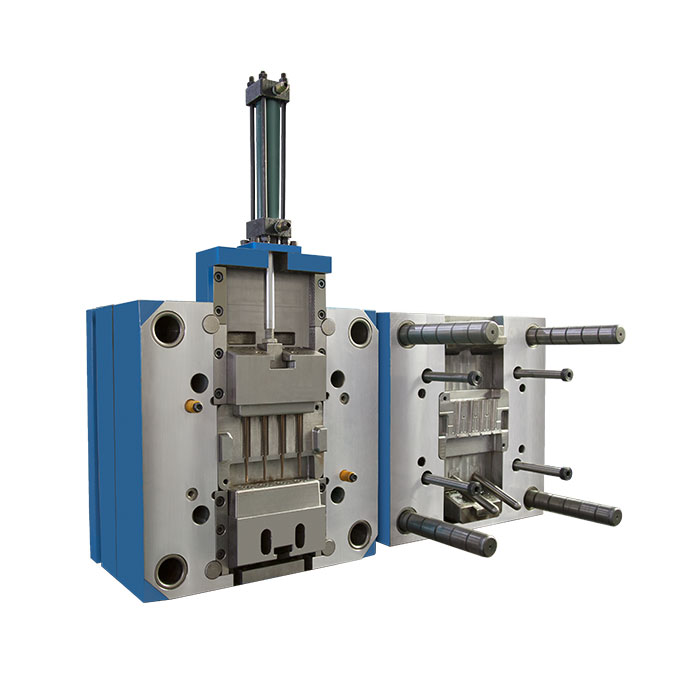

Medical TPE Mold

Design is the source of a high-quality mold, one good mold design will be half success, USM uses the world's leading software to analyze products and make DFM reports and mold flow analysis to eliminate the appearance of defective and defective products from the source when design, to reduce the changes and saving development time. USM relies on advanced equipment to manufacture molds to ensure that all parts meet the requirements and achieve high-quality mold life.

Features of Medical TPE Mold

1. Since medical plastic products can not be flashed, the finish requirements of the products are relatively high, and the mold steel generally uses S136 stainless steel series steel;

2. Because of the large amount of medical plastic products, the mold life requirements are also high, generally requiring a life of 1,000,000 mold times, and the molds are all made of heat-treated steel;

3. Many medical plastic injection molding products use PVC compound, and PVC is a strong acid and corrosive plastic, so the steel is made of stainless steel;

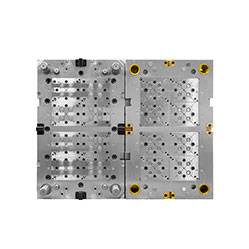

4. Because of the large number of medical plastic products, disposable products generally open multiple cavities, such as 32 points, 64 points, etc.;

5. The precision requirements of medical plastic molds are relatively high and there can be no flashes;

6. There are many small and slender needle tube products for medical injection molds products, and these plastic molds have higher cooling requirements;

7. In order to reduce the injection cycle, save runner materials, and achieve injection filling balance in medical multi-cavity molds, hot runners are generally used;

8. The thimble lubricating oil and release agent must not be used in medical molds during injection, so the tolerance of the mold is relatively high, otherwise, the ejector pin will be easily broken;

9. Many small and slender products of medical products are not easy to fill and vent during injection molding, the mold is vacuumed before filling to evacuate the air in the mold after the mold is closed, so that the product will not be trapped, which is good for filling.

English

English русский

русский