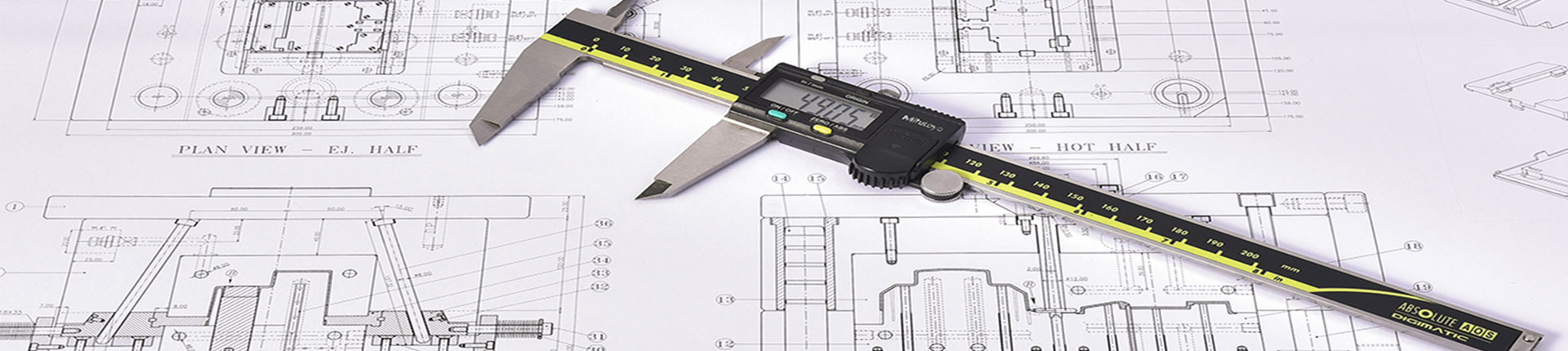

Medical Mold Injection Product

Different requirements will have different mold steel and products material, USM will choose the mold steel material according to the product requirements and function to achieve zero harm for users, that is the basic standard, including the anti-rust and anti-deformation, they will also be taken into consideration in the early stage during design processing.

Medical Mold Supplier Characteristics

1. It is non-toxic to the body, has no pyrogenic reaction, no "three causes" (carcinogenic, teratogenic, gene mutation) effect, no damage neighboring tissues, no interfere with the body's immune mechanism, and does not cause surface calcification of materials;

2. When the material is in contact with blood, it has good anticoagulant performance, the injection moulding medical products does not cause the reduction of blood cells after hemolysis and cause protein denaturation in the blood, and no damage to the formed components of the blood;

3. When the material is implanted in the body, it has sufficient chemical stability and physiological inertia, and the physical and mechanical properties do not change significantly (degradable materials are not included).

English

English русский

русский