Medical Plastic Injection Mold

For medical plastic components manufacturer, it means that medical supervisors are required to supervise and manage the materials used to manufacture the equipment, the medical injection mold parts are designed to withstand high temperatures and chemical corrosion. In this way, it can handle frequent sterilization cycles and any other medical or bodily fluids that come into contact with it.

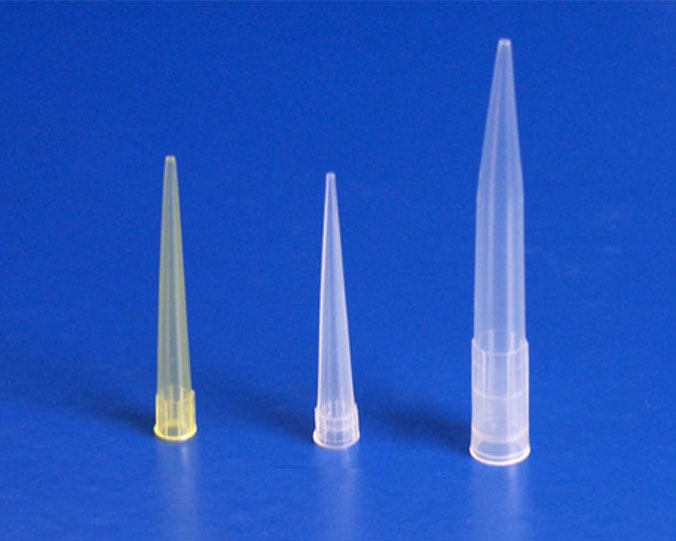

Injection Moulding Medical Products

Medical Injection Molds Advantages

1. Medical injection molds are versatility

2. Medical injection mold is easy to disinfect

3. Higher security

4. Injection molding medical products improve the quality of life

5. High-cost performance

6. Environmental protection

7. Medical decvice injection molding has potential for future innovation

Medical Device Plastic Injection Moulding Application

1. Patient care series

2. Diagnostic equipment series

3. Drug filtration series

4. Shell and component series

5. Disposable medical supplies series

6. Surgical instrument series

7. Orthopedics product series

8. Heart product series

9. Ophthalmology treatment instrument series

10. Healthcare components and equipment series

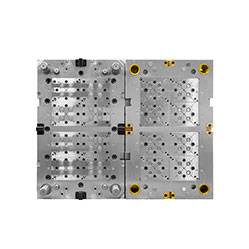

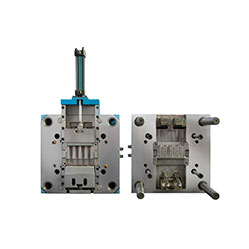

The medical device injection moulding parts are highly specialized and precise, and have precise and detailed requirements for sterility and supervision, these requirements are much higher comparing other industries. A dust-free injection molding shop can help ensure that particulate matter, that is dust, airborne organics, or vaporized particles will not contaminate the plastics that will make up medical device injection molding components.

English

English русский

русский