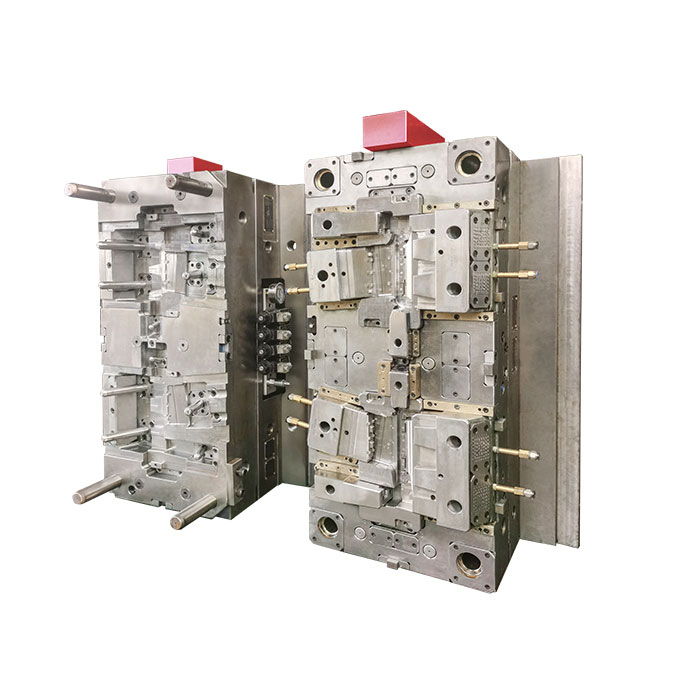

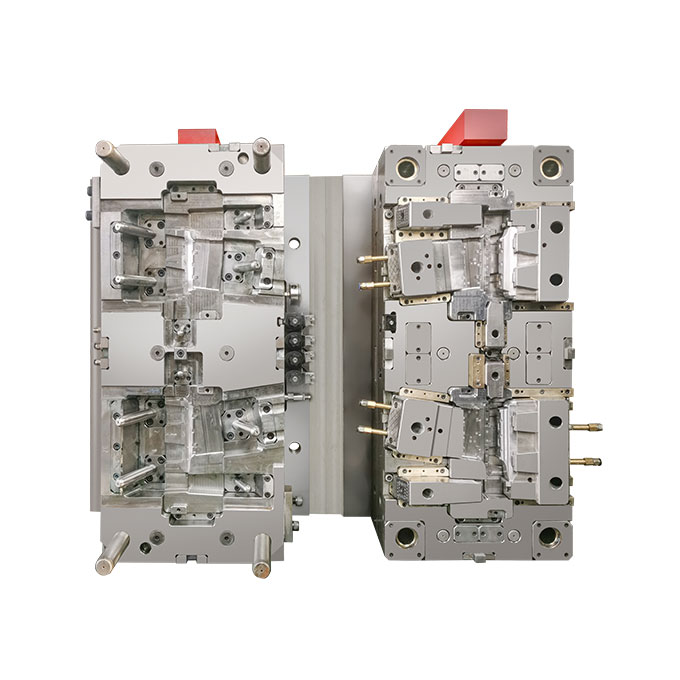

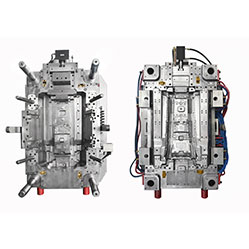

Automotive Mold Supplier

Nowadays, car influences our life everywhere, with the continuous development of society, people's requirements for cars are getting higher and higher. Not only for good performance and passability, but also the exterior and interior interiors of cars are required to be beautiful, comfortable and meet aesthetic requirements. The automtive interior parts are mainly are made by plastic, so the injection molding quality is an important factor to affect the interior and exterior of automotive.

The Main Points To Make Automotive Mold

1. Accuracy control of the coaxiality of the fan shaft hole;

2. The rotation function requires the flash control of the hole;

3. Deformation control of the shell;

4. Mold manufacturing precision control etc.

Don't Hesitate to Contact Us Now.

English

English русский

русский