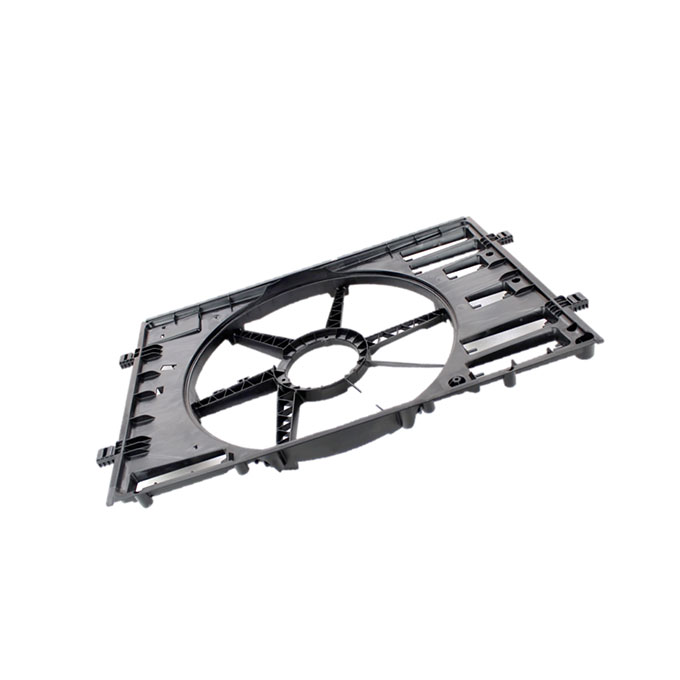

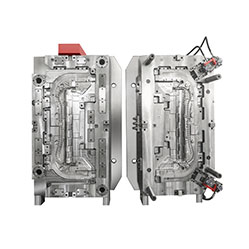

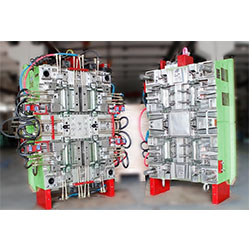

Automotive Fan Mould

Normally, the plastic with glass fiber ddition material products will be easy to deform, the main reason is that the shape is cylindrical, like our hair. due to the length of the glass fiber is different, the XYZ direction in plastic layout is also different, so the products will have different shrinkage due to the inconsistency of internal molecular orientation, and deformation will be same. so we will make pre-deformation for the materials with glass fiber.

Don't Hesitate to Contact Us Now.

English

English русский

русский