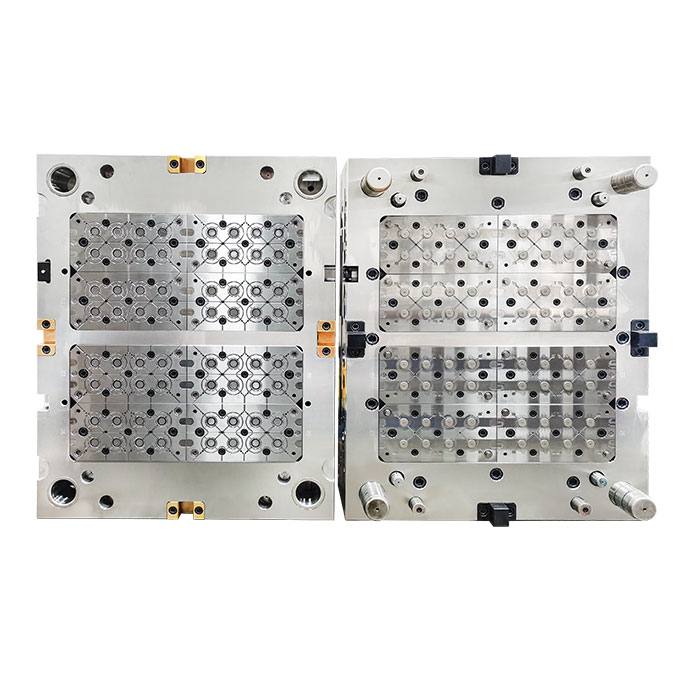

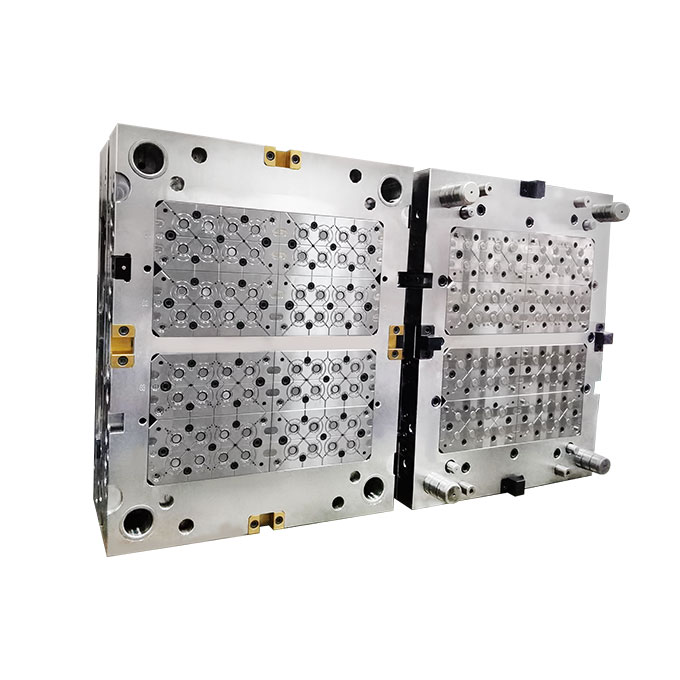

64 Cavities Plastic Injection Mould

This mold will use 16 pin-points hot nozzles for gating, and one nozzle will control 4 pieces of parts gating in order to achieve filling balance.

Product material: PE material in medical-grade

Mold steel: S136 HRC 52-54

Mold life: 1 million

Hot runner brand: mold master

Mold base: LKM

Surface finishing: texture

Mold lead time: 7 weeks

Don't Hesitate to Contact Us Now.

English

English русский

русский