0769-8539-0209

/

+86-15158220988

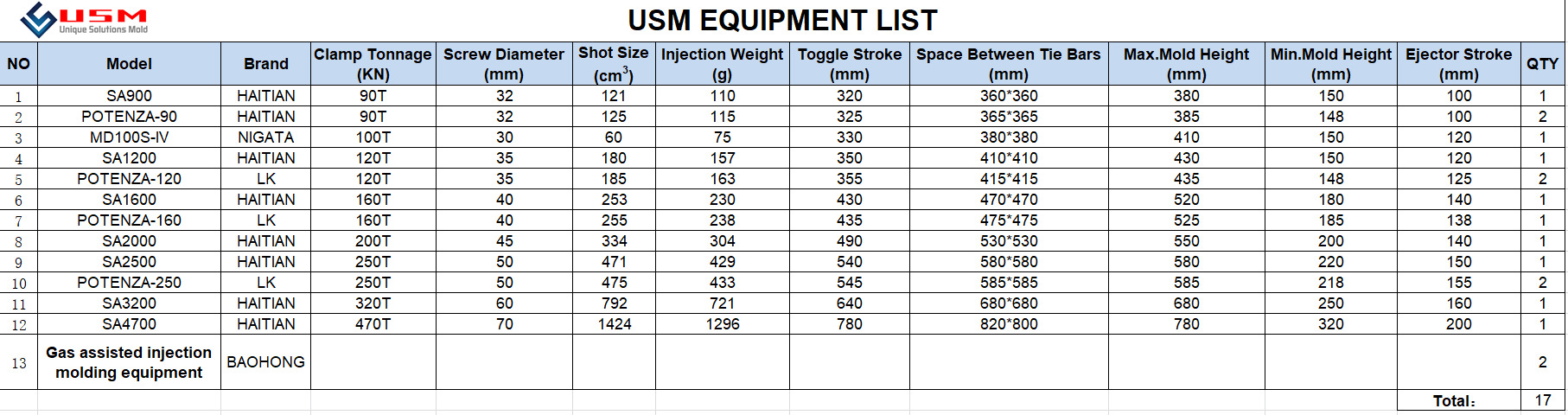

USM is a professional one-stop service for plastic injection molding companies in China, with our rich experience by mold-making capabilities, we ensure that mass products can be manufactured in the shortest time. There are 15 sets of plastic injection molding machines in our workshop, from 80T to 480T with an automated robot to ensure continuous and stable mass production, The weight of injection molded products ranges from 18 grams to 2000 grams. We provide 24 hours a day & 7 days a week automatic production service. And also we produce a wide range of plastic resins, like ABS, PC, PC+ABS, PP, PP+GF, PA, PA66+GF, PMMA, POM, PE, PPS+GF, TPE, TPU, PEEK, etc.

Not only we can produce over-plasticized equipment, double color (2K parts), and insert molding, but also we have 4 sets of gas assisted injection moulding production equipment that can produce gas-assisted injection parts too.

USM will choose the suitable mold steel and mold life according to the product quantity in order to save the cost for our customers, and also consider the different orders to make different lead time, whether it is a small batch order or large batch order will be all pleased.