0769-8539-0209

/

+86-15158220988

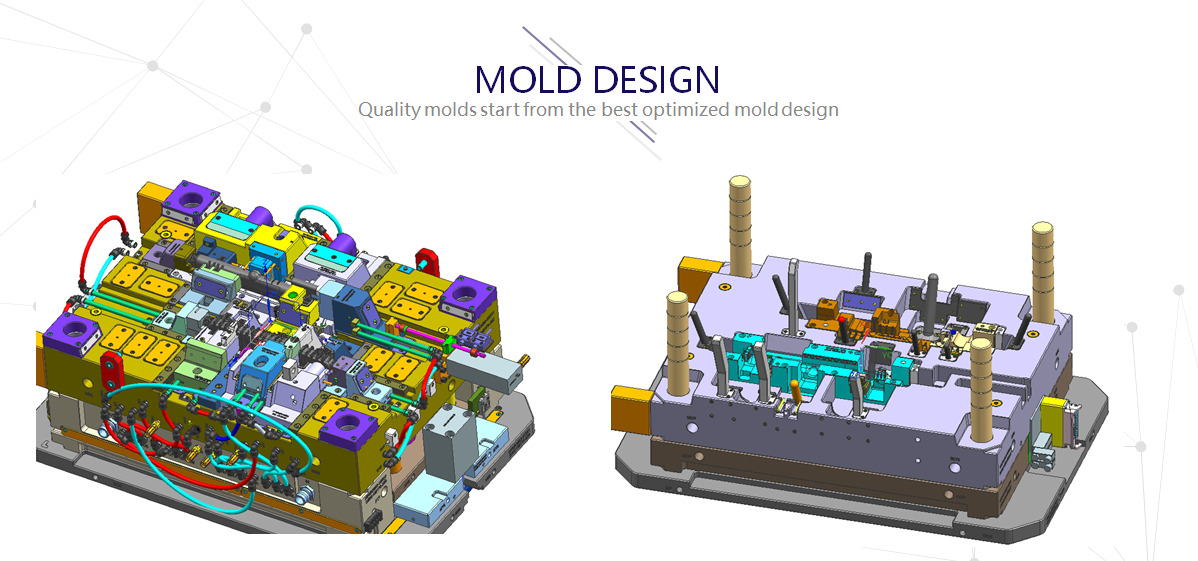

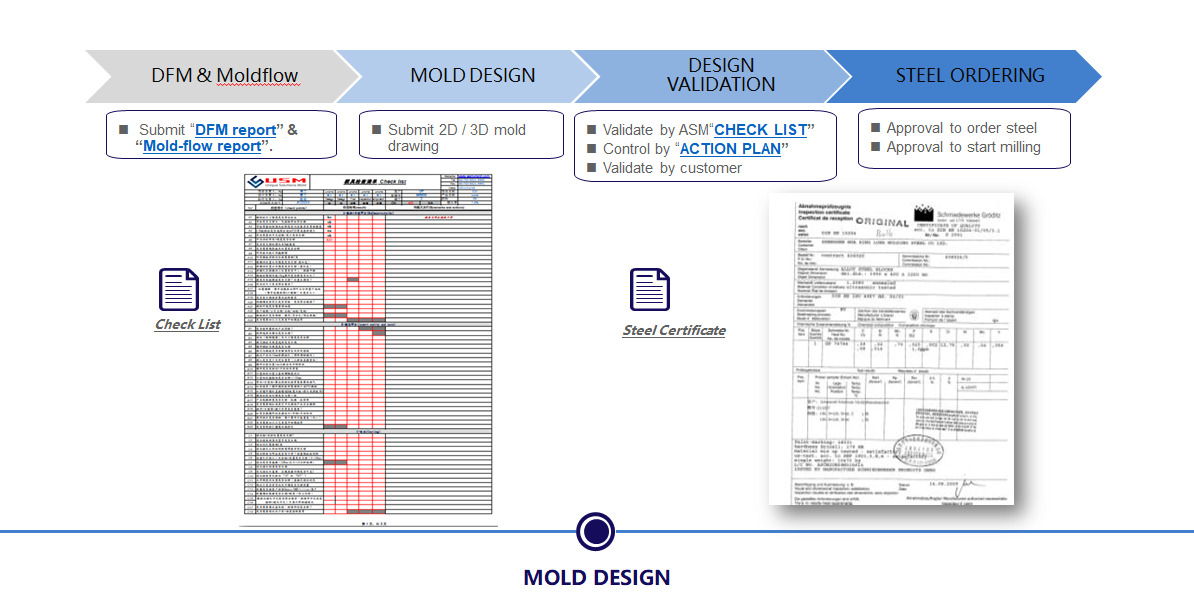

We always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together, and give their own professional advice from mold making side, in order to reduce part development time and changes, and also save the mold cost, etc. to give our professional advice, so that all of our customers can enjoy the one-stop service at USM.

There are 5 designers with more than 15 years of rich experience in this industry, their experience can help us to avoid some mistakes during design, and eliminate many potential risks in the early design stage. Realize all the subsequent work can be followed.

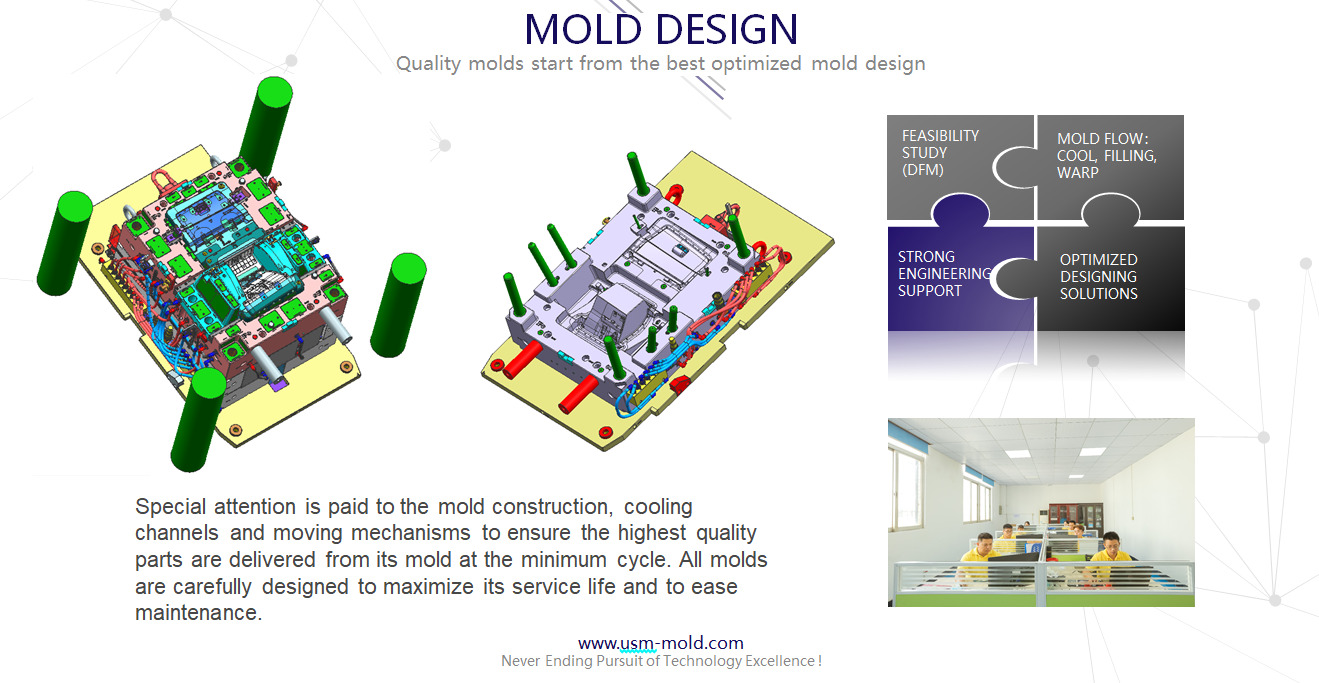

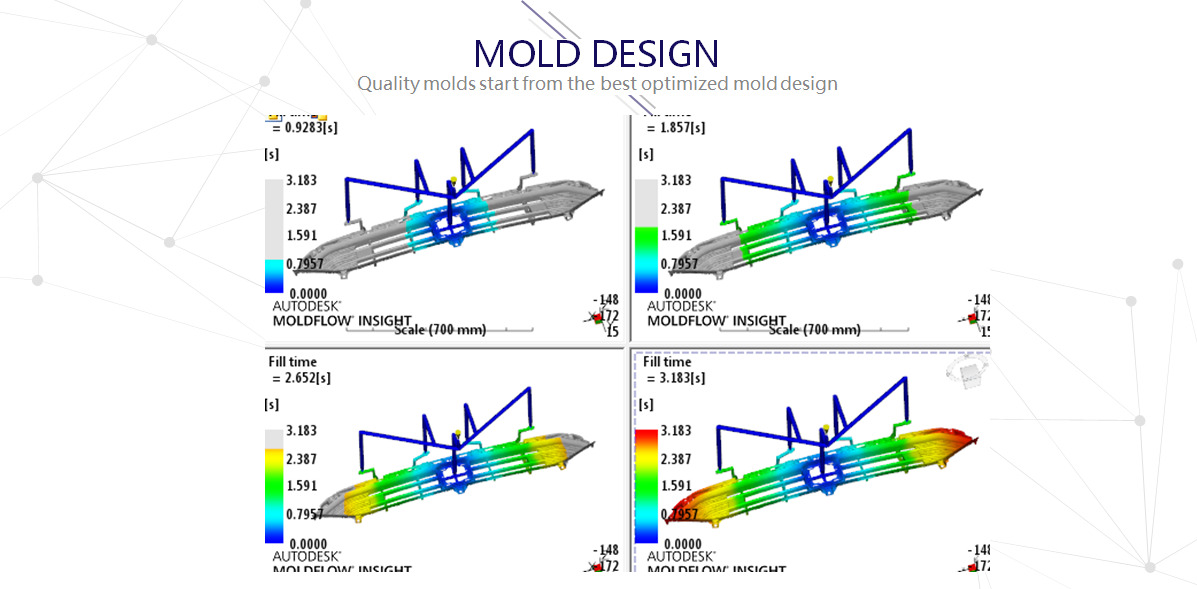

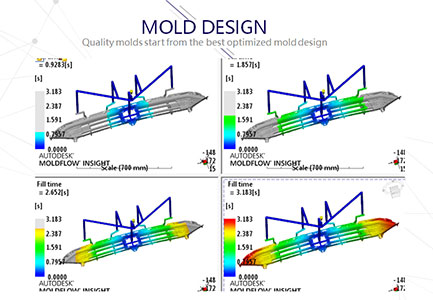

We always pay attention to the mold structure reliability, the efficiency of the cooling system, and the degree of automatic production to ensure that the high-quality products can be produced in the shortest cycle time, all molds are designed carefully and checked the maximize the mold life.

We are specialized in gas-assisted molds, medical injection molds, water-assisted molds, 2K molds & Overmolding and pre-deformation, and other complex mold projects. Our rich professional knowledge makes us are outstanding from other companies.

Here is the software our engineers are using:

CAD /CAM Software

AUTOCAD 2007

UG NX8.5 CAD

UG NX8.5 CAM

Pro-e Wildfire Version 5.0

Autodesk Simulation

Moldflow Insight 2015